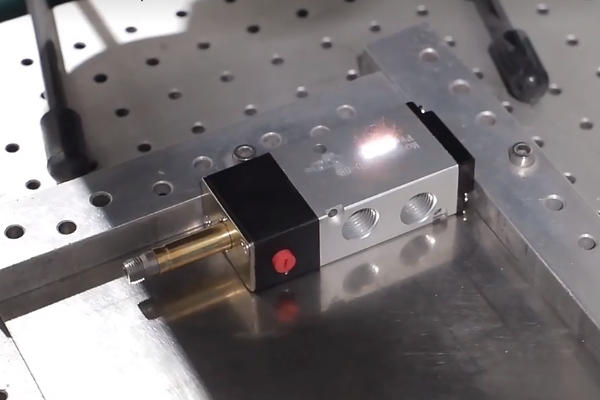

Pneumatic systems are widely used in various industries due to their efficiency and reliability. One of the critical components in these systems is the pneumatic valve, which controls the flow of compressed air. Understanding the different types of pneumatic valves is essential for technicians to ensure optimal system performance and maintenance.

Pneumatic actuators are crucial components in numerous industrial systems, offering reliable and efficient motion control. These devices convert compressed air into mechanical motion, making them indispensable in various engineering fields. This comprehensive guide explores the fundamentals of pneumatic actuators, their types, working principles, applications, and advantages, providing valuable insights for engineers and industry professionals.

Pneumatic tubes are essential components in various industries, providing efficient transport of materials and fluids through pressurized air systems. Understanding the types of pneumatic tubes and their applications can help buyers make informed decisions, ensuring optimal performance and cost-effectiveness.

Pneumatic systems are essential in various industrial applications, utilizing compressed air to generate motion and control. Understanding the components and their functions is crucial for engineers working with these systems. This article delves into the intricacies of pneumatic components, their types, and their advantages, providing a comprehensive guide for those interested in the subject.

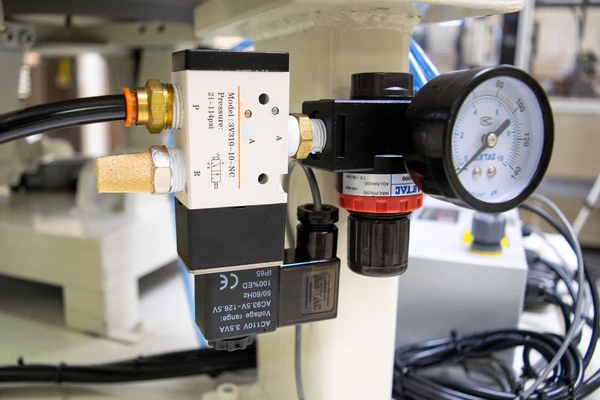

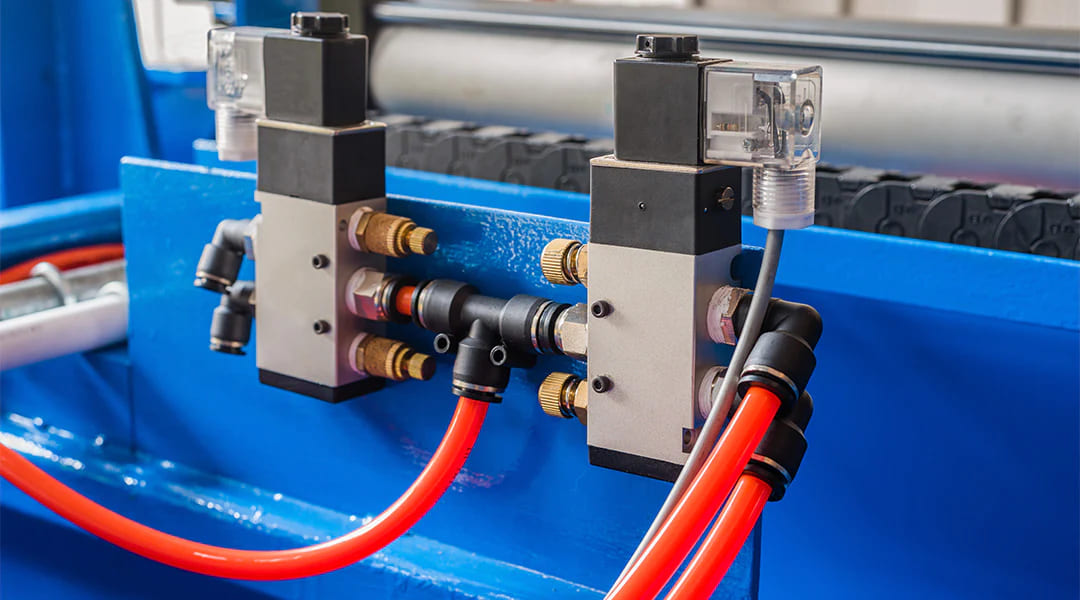

Pneumatic solenoid valves are vital components in many industrial applications, providing efficient control of airflow in various systems. These valves are essential for automation processes, enhancing the performance and reliability of machinery and equipment across numerous industries. By understanding the function, types, applications, and maintenance of pneumatic solenoid valves, engineers can optimize their use in a variety of settings.

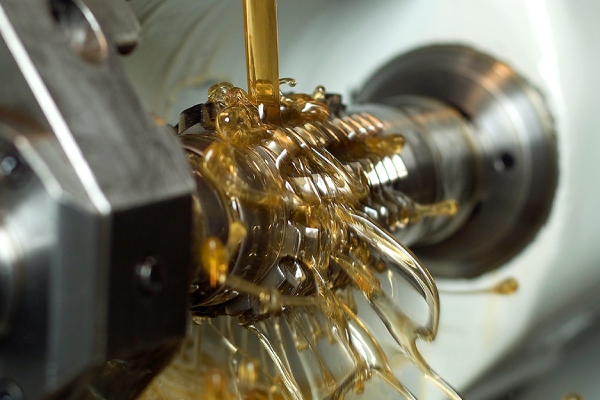

Lubricating pneumatic cylinders is crucial for maintaining their efficiency and longevity in industrial settings. Without proper lubrication, cylinders can experience increased wear, leading to costly downtime and repairs. This guide will walk you through the essential steps and best practices to ensure your pneumatic cylinders are always in top condition.

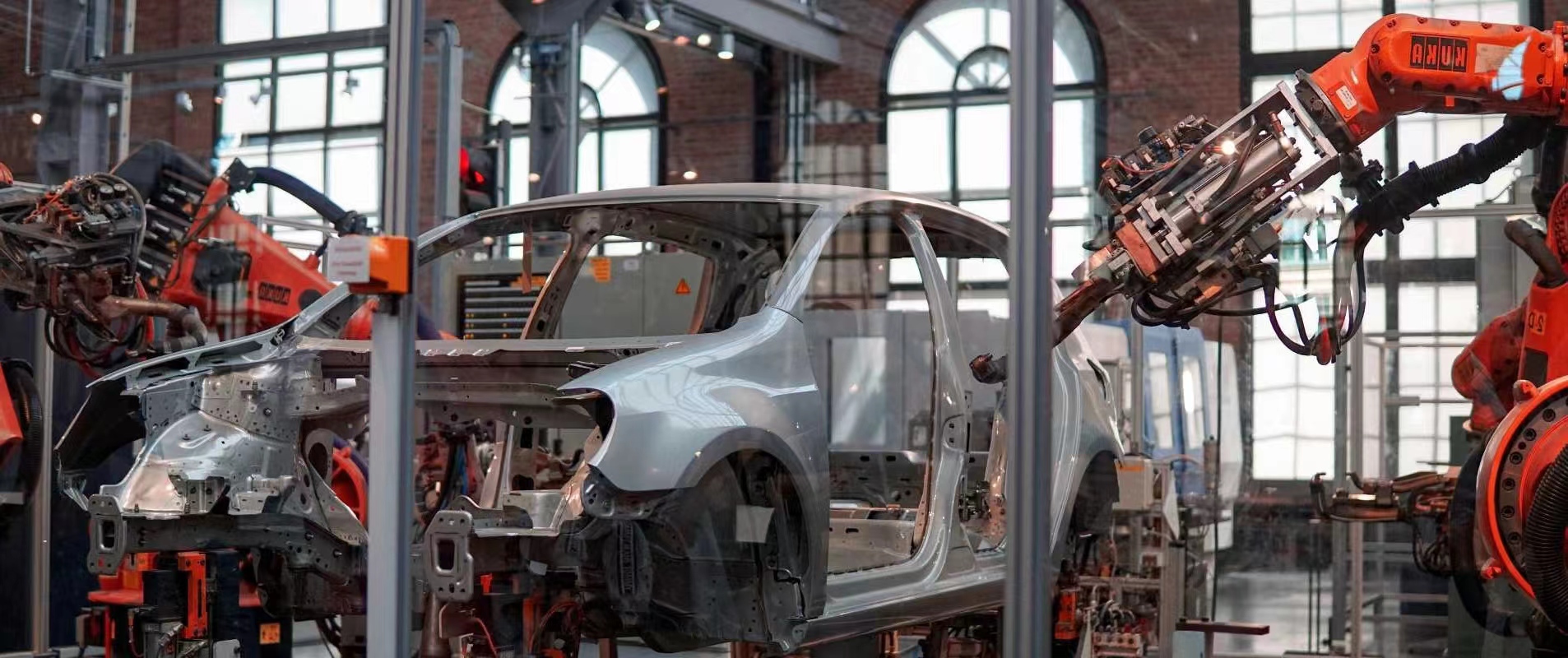

Pneumatic systems play an important role in various industries, offering versatile, reliable, and cost-effective solutions for automation and control. These systems utilize compressed air to power a range of mechanical processes, ensuring high efficiency and precision. Their application spans across numerous sectors, from automotive manufacturing to food processing, highlighting their importance in modern industrial operations.