Pneumatic Cylinder & Actuators

China Pneumatic Cylinder Manufacturer

Gymbela, your trusted pneumatic cylinder manufacturer and wholesale supplier. With 25 years of experience in pneumatic cylinder development and production, we are an ideal choice for your business.

Nabízíme flexible MOQ and wide range of customization options, so whether you run a large-scale or small-batch business, you can always find out the right solution.

Our cylinders boast a lifespan of up to 300,000 cycles, reducing your maintenance costs and enhancing production efficiency.

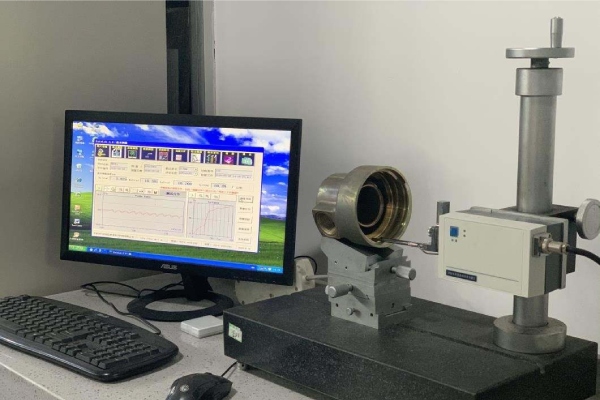

All our products undergo 100% professional testing, providing a continuous assurance of stable quality.

Choose Gymbela for your exceptional pneumatic cylinders, Custom solutions, professional advice, and reliable after-sales support.

How does Pneumatic Air Cylinder Work ?

A pneumatic air cylinder uses compressed air to generate linear motion in a cylindrical chamber. The compressed air creates a force imbalance, moving a piston connected to a rod. This linear motion is harnessed to perform tasks such as moving machinery components or actuating valves. Pneumatic cylinders are appreciated for their simplicity, reliability, and cost-effectiveness. They are commonly employed in manufacturing, automotive, aerospace, and robotics, particularly in applications where precise force and speed control are not crucial.

Table Of Contents

It is not easy to introduce all aspects of custom Pneumatic Cylinder, so we have prepared a lot of information on this page for you to dive into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

General Applications For Pneumatic Cylinders

Our Pneumatic Cylinders are known for excellent performance and reliability, perfect for various fields like industrial automation, manufacturing, and production lines. Boost creativity, improve efficiency, and give your business a vibrant upgrade!

Fabrication equipment

Packing Equipment

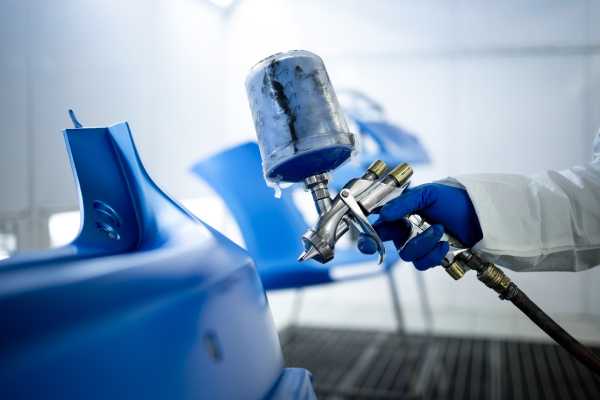

Paint spraying equipment

Filling equipment

Material Handling Machines

Robotic end of arm tooling

Air-Powered Tools

Types of Pneumatic Cylinder & Actuator

Pneumatic air cylinders are devices that use compressed air to generate linear or rotary motion. They are widely used in various industrial applications for tasks such as pushing, pulling, lifting, and rotating. There are three main types of pneumatic air cylinders: single-acting cylinders, double-acting cylinders, and rotary cylinders.

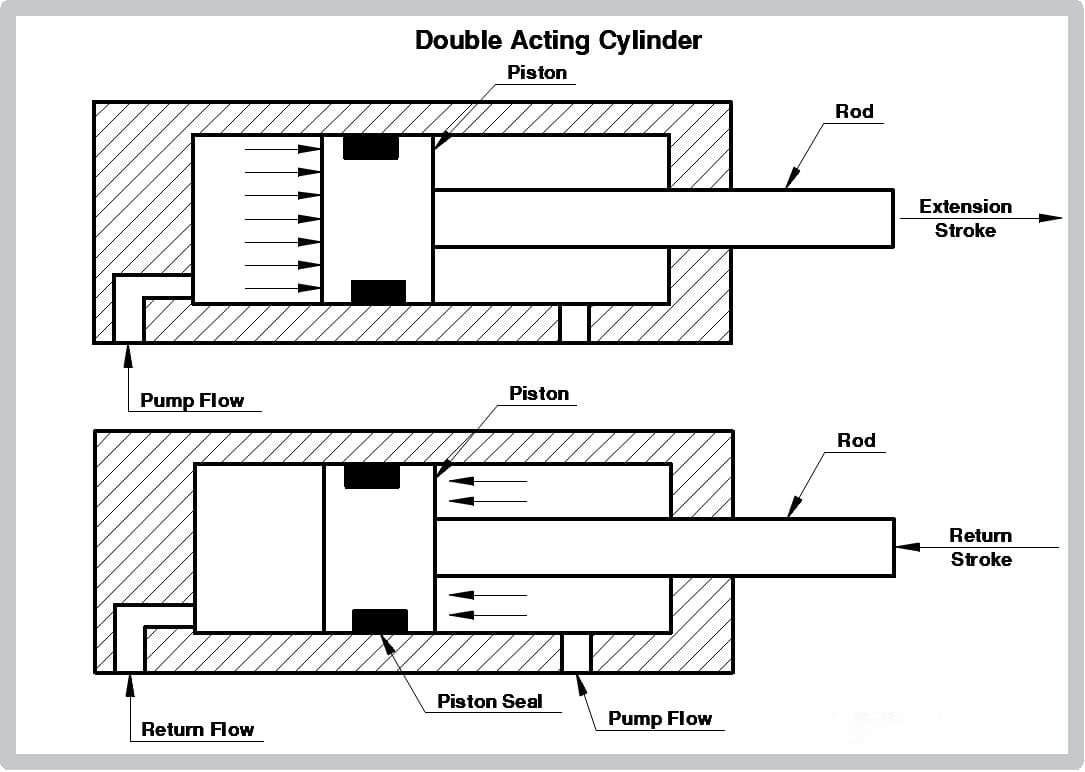

Dvojčinný pneumatický válec

- Provide bi-directional force and precise control

- applications like material handling, conveyor systems, and machine tools.

- More versatile than single-acting cylinders due to the ability to control both extension and retraction.

Double-acting cylinders use compressed air to generate force in both directions. They have a piston with two air chambers on either side, allowing for controlled movement in both the extend and retract strokes.

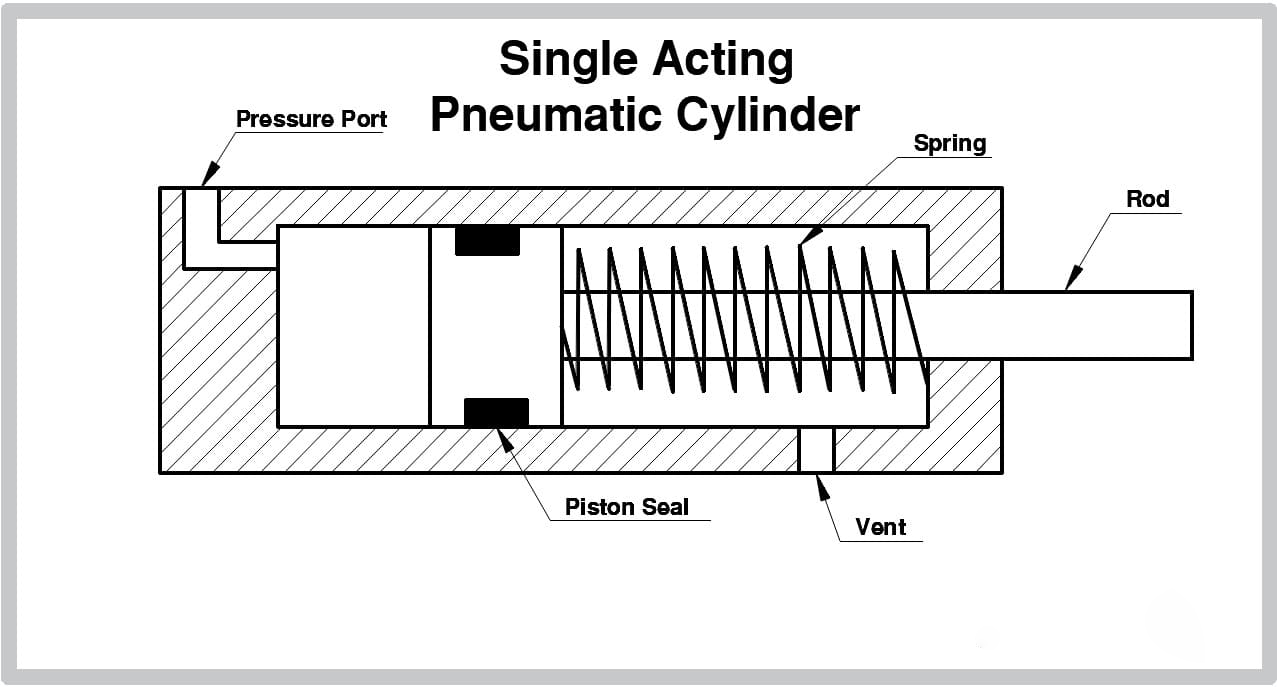

Jednočinný pneumatický válec

- Simple design and cost-effective.

- Suitable for applications where force is required in one direction

- Applications such as clamping, lifting, and pressing.

Single-acting cylinders use compressed air to create force in only one direction. They typically consist of a cylindrical tube, a piston, and a spring. Compressed air is used to push the piston in one direction, and the spring returns it to its original position when the air pressure is released.

Rotační pneumatické válce

- Ideal for tasks such as turning valves, rotating tools, and indexing

- Available in various designs, including vane-type and rack-and-pinion.

- Suited for applications where linear motion is impractical.

Rotary cylinders convert pneumatic pressure into rotary motion. They are used when rotational movement is required instead of linear motion. The cylinder’s piston is connected to a shaft, causing it to rotate when the piston moves.

Custom Pneumatic Air Cylinders

Wanna dig deeper in Pneumatic cylinders ?

and our engineer will contact with you within 24 hours.

Estimated Price Pneumatic Cylinders

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation.

| Název | Bore(MM) | Stroke(MM) | Price | Stock MOQ | Custom MOQ |

|---|---|---|---|---|---|

| XSN Series ISO6432 Standard Pneumatic Cylinders | 8~40 | 25~300 | 4.6~20.1 USD | Start From 20 Pieces | 100 Pieces |

| XNG Series ISO15552 Standard Pneumatic Cylinders | 32~320 | 50~1000 | 8.9~1037.7 USD | Start From 20 Pieces | 100 Pieces |

| SID Series ISO15552 Double Acting Pneumatic Cylinders | 32~200 | 50~1000 | 13~496.8 USD | Start From 20 Pieces | 100 Pieces |

| ACQ Series Thin Compact Pneumatic Cylinders | 12~125 | 5~50 | 2.9~139.4 USD | Start From 20 Pieces | 100 Pieces |

| MA Series Stainless Steel Mini Pneumatic Cylinder | 16~40 | 25~300 | 5.7~20.1 USD | Start From 20 Pieces | 100 Pieces |

| MAL Series Aluminum Alloy Mini Pneumatic Cylinder | 16~40 | 25~300 | 4.6~16.6 USD | Start From 20 Pieces | 100 Pieces |

| TN Seires Twin Rod Pneumatic Cylinder | 10~32 | 10~200 | 7.8~39.5 USD | Start From 20 Pieces | 100 Pieces |

| CDU Series Free Installation Pneumatic Cylinder | 6~32 | 5~50 | 4.2~14.1 USD | Start From 20 Pieces | 100 Pieces |

| MGPM Series Compact Tri-rod Pneumatic Cylinder | 12~100 | 10~100 | 20.3~497.5 USD | Start From 20 Pieces | 100 Pieces |

| CPT Series Booster Pneumatic Cylinder (Hydraulic ) | 63~160 | 50~200 | 177.2~1916.3 USD | Start From 20 Pieces | 100 Pieces |

| CY Series Rodless Pneumatic Cylinder | 20~40 | 200~2000 | 62.8~295.4 USD | Start From 20 Pieces | 100 Pieces |

The Process Flow & Duration Estimation

We ensure top-quality products through rigorous adherence to industry standards. Our processes are ISO9001:2005 certified, and our commitment is validated by SGS and ROHS certifications, assuring you of uncompromised quality and reliability.

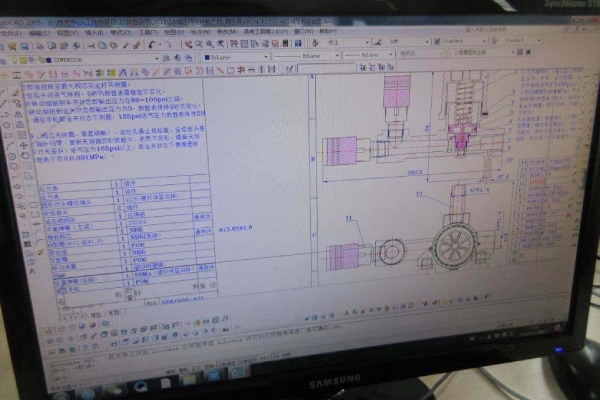

Step 1: Product Design Communication (3-7 days)

As leading custom pneumatic cylinder manufacturers, we engage in comprehensive communication with you to ensure a clear understanding of your product vision and requirements. We are committed to being the best pneumatic air cylinder manufacturer, focusing on clarifying specifications to establish a shared understanding of the pneumatic cylinder design. Your feedback is welcomed, and we engage in multiple discussions until you are satisfied with the design.

Step 2: Pneumatic Cylinders Sampling (7-14 days)

Once the design meets your expectations, we, as a top pneumatic actuator manufacturer, produce samples for your review. We understand the importance of samples to you, ensuring they meet your standards in terms of quality and appearance. Your feedback is actively sought, and necessary modifications are made to ensure the final pneumatic cylinder product aligns with your expectations.

Step 3: Pay The Bill (within 1 day)

After you confirm satisfaction with the samples and decide to proceed, the payment process is made convenient for you. As one of the best pneumatic cylinder manufacturers, we provide clear payment terms as part of our commitment to transparent and efficient transactions.

Step 4: Bulk Manufacturing (30-45 days)

As a reliable pneumatic air cylinder manufacturer, upon receiving your order, we swiftly initiate bulk manufacturing. We understand the importance of timely delivery to you, while also ensuring that each pneumatic cylinder meets high-quality standards. We regularly update you on the production progress, ensuring you have a clear understanding of the entire process.

Step 5: Shipping (10-15 days)

After production is complete, we, as your trusted pneumatic cylinder manufacturers, carefully package and arrange for shipping. We provide detailed logistics information, allowing you to track the pneumatic actuators’ shipping progress. Our goal is to ensure the pneumatic cylinders reach you safely and promptly.

Want to know how to compress lead times?

With just a click, unlock a world of swift solutions! Connect with our engineers effortlessly to tailor-make a speedy pneumatic air cylinder experience.

Basic Knowledge of Pneumatic Cylinders

Explore our blog for insights into the latest pneumatic technology. Stay updated on cutting-edge components and solutions. Choose us to stay ahead in the world of technological innovation.

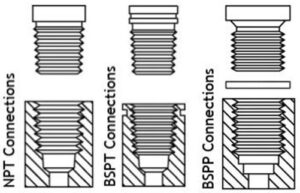

NPT vs. BSP Air Filter: A Beginner’s Guide to Choosing the Right One

NPT and BSP are two different standards for screw threads used to connect pipes and fittings. They determine how the parts fit together, how tight the seal is, and whether or not the connection will leak. Let’s take a closer look at each:

FRL Units Explained: Functions, Benefits, and Applications in Pneumatic Systems

Pneumatic systems are widely used in various industries for their ability to perform high-precision tasks using compressed air. However, to ensure these systems operate at their peak performance, the quality of the air they use is crucial. This is where the FRL unit comes into play.

What is NFPA Pneumatic Cylinders: A Comprehensive Guide

NFPA pneumatic cylinders are pneumatic actuators designed according to the standards set by the National Fluid Power Association (NFPA). These cylinders are specifically engineered to be interchangeable across various manufacturers

What is a Pneumatic System in an Aircraft?

The pneumatic system in an aircraft is a collection of components designed to compress, store, and distribute pressurized air to various aircraft systems. This system provides a consistent flow of compressed air, which is utilized for tasks such as cabin pressurization, air conditioning, and engine starting.

What is the ISO 6432 Standard Mini Pneumatic Air Cylinder?

Automation systems and industrial equipment often require compact and efficient actuators to perform mechanical tasks. The ISO 6432 standard mini pneumatic air cylinder delivers high-performance linear motion in a small package.

A Comprehensive Guide to Avoiding Pitfalls When Purchasing Pneumatic Cylinders from China

Purchasing pneumatic cylinders from China can be a cost-effective and reliable option, but it comes with its own set of challenges. As a procurement professional, you need to navigate through a maze of potential pitfalls, from selecting the right supplier to ensuring product quality and managing logistics. This guide is designed to help you make informed decisions, avoid common mistakes, and ensure a smooth purchasing process.

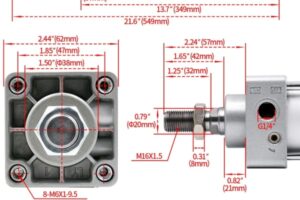

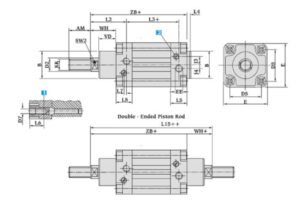

How to Measure Pneumatic Cylinder Size

When working with pneumatic systems, accurately measuring the size of pneumatic cylinders is crucial for ensuring optimal performance and compatibility. This guide will walk you through the essential steps and considerations for measuring pneumatic cylinder size effectively, providing a thorough understanding to engineers.

How to Calculate Pneumatic Cylinder Force in kg

Understanding the force exerted by pneumatic cylinders is crucial for industrial applications. Miscalculating this force can lead to equipment failure or inefficiencies. This guide provides a step-by-step approach to accurately calculate pneumatic cylinder force in kilograms.

How to Control the Distance of a Pneumatic Cylinder: A Comprehensive Guide

In the world of engineering, the precise control of a pneumatic cylinder’s distance is crucial for optimizing performance and efficiency. Without accurate control, applications can suffer from inefficiencies, inaccuracies, and potential failures. This guide explores various methods to achieve precise control over pneumatic cylinder distance, ensuring your pneumatic systems operate at peak performance.

Which Gas is Commonly Used in Pneumatic Systems?

Using the right gas in pneumatic systems is crucial for optimal performance and safety. Nitrogen and compressed air are the most frequently used gases in various industries. Understanding their applications, benefits, and safety considerations can help industry professionals make informed decisions. This article delves into the specifics of these gases, exploring their unique properties, applications, and the reasons for their widespread use in pneumatic systems.

Common Pitfalls Sourcing Pneumatic Cylinders from China

To ensure you procure pneumatic cylinders from China with confidence, we’ve compiled a list of common quality issues. This aims to enhance your purchasing experience, providing reliability and efficiency while ensuring the received products meet the highest standards, safeguarding your interests and confidence.

01 :Sealing Performance: Due to the industrial applications of pneumatic cylinders requiring high sealing performance, the quality of seals becomes a crucial issue. Low-quality seals may lead to air leakage, affecting the cylinder’s performance.

02:Surface Treatment: Some manufacturers may have issues with surface treatments, such as uneven coatings or susceptibility to corrosion, which can reduce the durability and corrosion resistance of pneumatic cylinders.

03:Accuracy and Dimensional Stability: Pneumatic cylinders require high precision, and dimensional instability can lead to operational problems, impacting production efficiency.

04:Material Selection: Low-quality materials can compromise the strength of the cylinder, making it prone to damage or failure. Wholesalers need to ensure that manufacturers use high-quality materials.

05:Process Control: The level of control and management in the manufacturing process directly affects product consistency and quality. Deficiencies in the manufacturing process can impact the performance and lifespan of the cylinder.

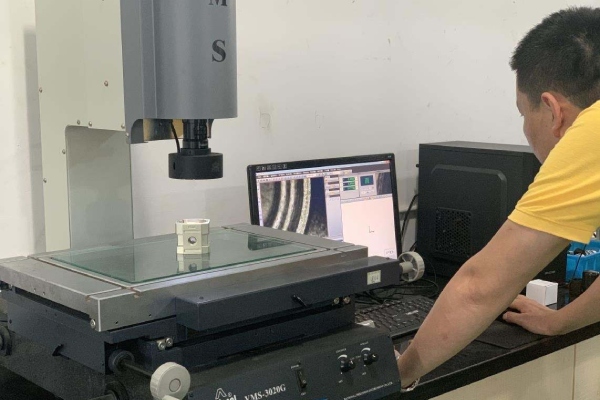

06:Performance Testing: Wholesalers should ensure that suppliers conduct rigorous performance tests on each pneumatic cylinder to ensure it complies with product specifications and customer requirements.

How Gymbela Control Quality

During the procurement process, you can request samples for testing, establish long-term partnerships with suppliers to have better control and assurance in terms of quality. Additionally, it is recommended to clearly outline quality standards and inspection requirements in the contract.

A Brief Self-Nomination, Why Choose Gymbela?

With 25 years of expertise, gymbela stands as a leading pneumatic cylinder & actuator manufacturer. Our advanced 2000 sqm facility, located in China’s pneumatic industry hub, We Operating within a cost-effective supply chain involving 300+ related factories, gymbela offers OEM/ODM services, ensuring ISO9001-certified quality.

- Podpořeno Čínou č. 1 pnematický průmyslový park

- 100,000 units Pneumatic cylinders Per Year.

- OEM/ODM Services Available.

- Pneumatic Components one-stop Sourcing Solutions.

- Lower Moq to 100 Pieces.

Choose gymbela for top-tier pneumatic solutions, combining manufacturing excellence and vast industry knowledge. Whether you seek bulk orders or custom solutions, gymbela caters to your needs. Contact gymbela now to secure a reliable partner for pneumatic excellence, benefiting from our stable supply chain and premium services.

Related Pneumatic Products

Pneumatic Valves

Achieve precise control and automation with GYMBELA’s Solenoid Valves. Our solenoid valves are designed for fast, accurate, and reliable switching of compressed air, making them ideal for a wide range of industrial applications. Key features include:

- Rapid response times for precise control

- High cycle life for increased longevity

- Wide range of voltage and connection options

- Robust construction for enhanced durability

Air Fliters & Regulator

Protect your pneumatic systems from contamination and extend the life of your components with GYMBELA’s high-quality Filters. Our filters remove solid particles, liquid aerosols, and even oil vapor from compressed air, ensuring optimal performance and efficiency. Key advantages include:

- High filtration efficiency for maximum protection

- Easy-to-replace filter elements

- Durable construction for long service life

- Wide range of sizes and filtration grades available

Airhose & Fittings

Ensure the seamless flow of compressed air throughout your system with GYMBELA’s premium Air Hoses. Designed for flexibility, durability, and efficiency, our air hoses offer the perfect solution for a wide range of industrial applications. Key benefits include:

- High-quality materials for enhanced longevity

- Wide range of hose sizes, lengths, and materials to suit various requirements

- Excellent resistance to abrasion, weather, and chemicals

- Easy installation and maintenance

The FAQs

To enhance your procurement efficiency, we’ve crafted a series of FAQs to address common issues and assist you in swiftly completing your purchasing tasks.

Is this cylinder suitable for my application ?

Gymbela recommend providing specific requirements for your application, including the needed force, speed, and other specific criteria, so our engineer can recommend the appropriate type of cylinder.

Does the size of this cylinder fit within my space constraints ?

Sure, Gymbela provide detailed dimensions and size information to ensure the cylinder can fit within your specified space.

Is the material of this cylinder corrosion-resistant ?

Yes, Gymbela manufacture cylinders using corrosion-resistant materials such as aluminum alloy 6063-T5 to ensure their reliability and durability in different environmental conditions.

What certifications do your suppliers have ?

Our factories adhere to relevant industry standards and regulations and possess the necessary certifications.such as ISO9001:2005,SGS,and ROHS. This helps ensure that the products we provide meet high-quality and safety standards.

Are additional discounts available for large-scale purchases ?

Yes, we are open to considering discounts for large-scale purchases, and we can tailor pricing plans for B2B customers to meet your budget requirements.

How do I choose a pneumatic cylinder?

When choosing a pneumatic cylinder, consider the following factors to ensure it meets your specific requirements:

01 Load Requirements: Determine the load the cylinder needs to bear, considering both vertical and horizontal loads, as well as any potential shocks or vibrations.

02 Stroke Length: Determine the stroke length of the cylinder, which is the distance the piston travels from one extreme position to another.

03 Speed: Consider the speed at which you need the piston to move. This involves cycle times in the working environment and production efficiency.

04 Operating Environment: Consider the environmental conditions the cylinder will be exposed to, including temperature, humidity, and any potentially corrosive gases or chemicals.

05 Installation Space: Determine the available installation space to ensure the selected cylinder fits within that space.

06 Cylinder Type: There are different types of cylinders, including single-acting and double-acting cylinders. Single-acting cylinders exert force in only one direction, while double-acting cylinders can generate force in two directions.

07 Materials and Seals: Choose appropriate materials to ensure the cylinder has sufficient durability in the specific environment. Additionally, the quality of seals is crucial, as they affect the performance and lifespan of the cylinder.

08 Control Method: Consider how you want to control the cylinder. Cylinders can be controlled manually, electrically, or pneumatically.

09 Cost: Finally, consider the cost of the cylinder. Ensure your choice falls within your budget and can provide the required performance.

When selecting a pneumatic cylinder, it's advisable to consult with the manufacturer or a professional pneumatic system engineer for more specific advice and customized solutions to ensure that the chosen cylinder meets your specific needs.

Can you offer customized solutions to our automation system?

Yes, we can provide customized cylinder solutions to seamlessly integrate with your automation system, enhancing production efficiency. tortor. Maecenas vestibulum mollis diam.

What is the lifespan of the cylinder ?

Our cylinders are designed for long-term use, and detailed information regarding lifespan and performance is available. We can also provide a reliability guarantee to safeguard your investment.

Do you provide training or technical support ?

We offer training and technical support to ensure that your team uses and maintains the cylinders correctly, maximizing system efficiency.

Can you offer a warranty or service agreement for the cylinders ?

Yes, we provide 1 year warranties and service agreements for our cylinders. The coverage includes defects in materials and workmanship, offering you peace of mind and protection for your investment。