Pneumatic Cylinder & Actuators

China Pneumatic Cylinder Manufacturer

Gymbela, your trusted pneumatic cylinder manufacturer and wholesale supplier. With 25 years of experience in pneumatic cylinder development and production, we are an ideal choice for your business.

Ofrecemos flexible MOQ and wide range of customization options, so whether you run a large-scale or small-batch business, you can always find out the right solution.

Our cylinders boast a lifespan of up to 300,000 cycles, reducing your maintenance costs and enhancing production efficiency.

All our products undergo 100% professional testing, providing a continuous assurance of stable quality.

Choose Gymbela for your exceptional pneumatic cylinders, Custom solutions, professional advice, and reliable after-sales support.

How does Pneumatic Air Cylinder Work ?

A pneumatic air cylinder uses compressed air to generate linear motion in a cylindrical chamber. The compressed air creates a force imbalance, moving a piston connected to a rod. This linear motion is harnessed to perform tasks such as moving machinery components or actuating valves. Pneumatic cylinders are appreciated for their simplicity, reliability, and cost-effectiveness. They are commonly employed in manufacturing, automotive, aerospace, and robotics, particularly in applications where precise force and speed control are not crucial.

Índice

It is not easy to introduce all aspects of custom Pneumatic Cylinder, so we have prepared a lot of information on this page for you to dive into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

General Aplicaciones For Pneumatic Cylinders

Our Pneumatic Cylinders are known for excellent performance and reliability, perfect for various fields like industrial automation, manufacturing, and production lines. Boost creativity, improve efficiency, and give your business a vibrant upgrade!

Equipos de fabricación

Equipos de envasado

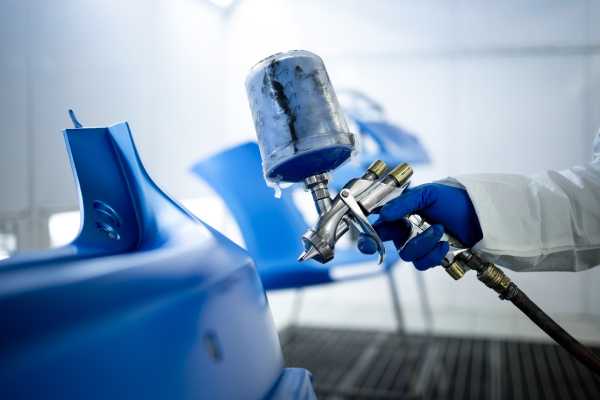

Equipos de pulverización de pintura

Equipos de llenado

Máquinas de manipulación de materiales

Herramientas robóticas de fin de brazo

Herramientas neumáticas

Tipos de Pneumatic Cylinder & Actuator

Pneumatic air cylinders are devices that use compressed air to generate linear or rotary motion. They are widely used in various industrial applications for tasks such as pushing, pulling, lifting, and rotating. There are three main types of pneumatic air cylinders: single-acting cylinders, double-acting cylinders, and rotary cylinders.

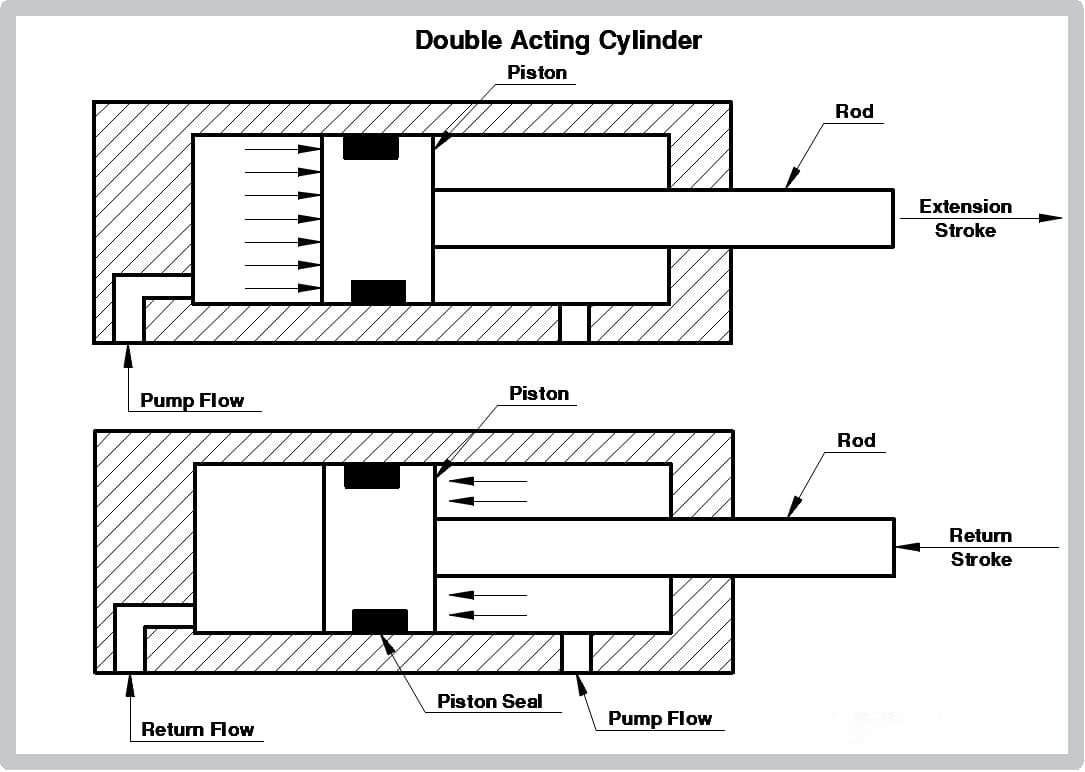

Cilindro neumático de doble efecto

- Provide bi-directional force and precise control

- applications like material handling, conveyor systems, and machine tools.

- More versatile than single-acting cylinders due to the ability to control both extension and retraction.

Double-acting cylinders use compressed air to generate force in both directions. They have a piston with two air chambers on either side, allowing for controlled movement in both the extend and retract strokes.

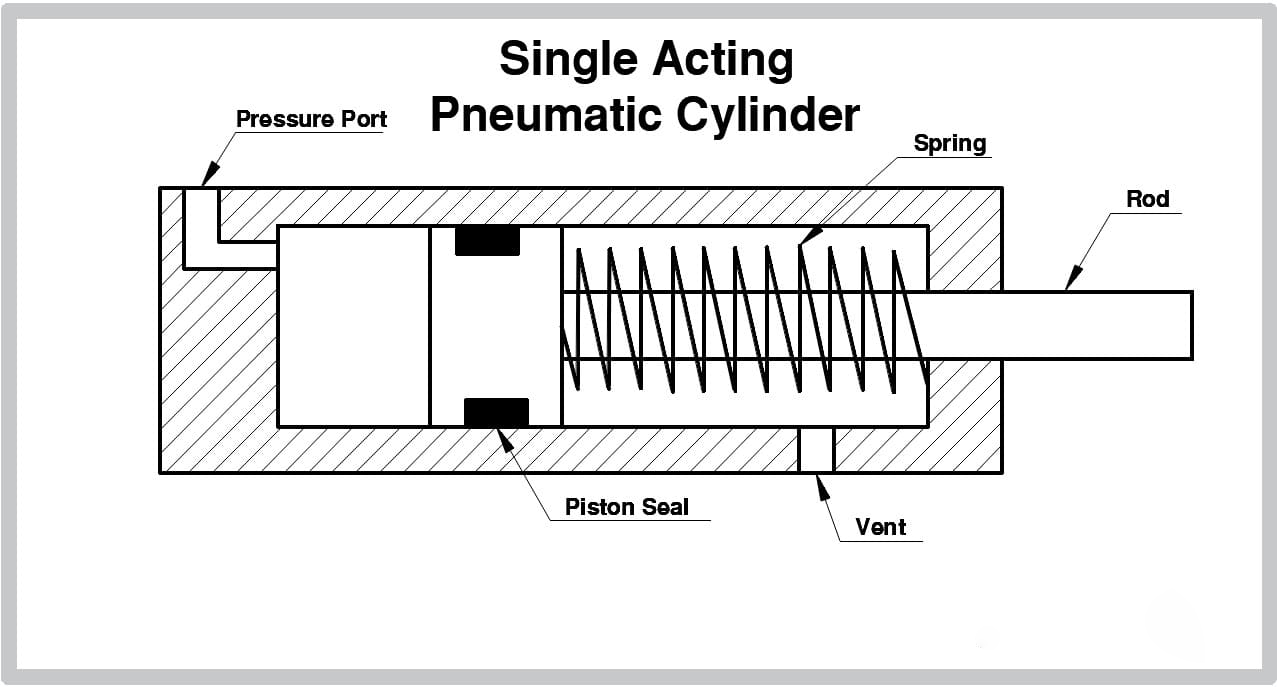

Cilindro neumático de simple efecto

- Simple design and cost-effective.

- Suitable for applications where force is required in one direction

- Applications such as clamping, lifting, and pressing.

Single-acting cylinders use compressed air to create force in only one direction. They typically consist of a cylindrical tube, a piston, and a spring. Compressed air is used to push the piston in one direction, and the spring returns it to its original position when the air pressure is released.

Cilindros neumáticos rotativos

- Ideal for tasks such as turning valves, rotating tools, and indexing

- Available in various designs, including vane-type and rack-and-pinion.

- Suited for applications where linear motion is impractical.

Rotary cylinders convert pneumatic pressure into rotary motion. They are used when rotational movement is required instead of linear motion. The cylinder’s piston is connected to a shaft, causing it to rotate when the piston moves.

Custom Pneumatic Air Cylinders

Wanna dig deeper in Pneumatic cylinders ?

and our engineer will contact with you within 24 hours.

Estimación Precio Cilindros neumáticos

Tenga en cuenta que el coste final depende del servicio personalizado que solicite, las especificaciones de las materias primas utilizadas, la legislación nacional pertinente y la distancia del transporte.

| Nombre | Bore(MM) | Stroke(MM) | Precio | Stock MOQ | MOQ personalizado |

|---|---|---|---|---|---|

| XSN Series ISO6432 Standard Pneumatic Cylinders | 8~40 | 25~300 | 4.6~20.1 USD | Start From 20 Pieces | 100 Pieces |

| XNG Series ISO15552 Standard Pneumatic Cylinders | 32~320 | 50~1000 | 8.9~1037.7 USD | Start From 20 Pieces | 100 Pieces |

| SID Series ISO15552 Double Acting Pneumatic Cylinders | 32~200 | 50~1000 | 13~496.8 USD | Start From 20 Pieces | 100 Pieces |

| ACQ Series Thin Compact Pneumatic Cylinders | 12~125 | 5~50 | 2.9~139.4 USD | Start From 20 Pieces | 100 Pieces |

| MA Series Stainless Steel Mini Pneumatic Cylinder | 16~40 | 25~300 | 5.7~20.1 USD | Start From 20 Pieces | 100 Pieces |

| MAL Series Aluminum Alloy Mini Pneumatic Cylinder | 16~40 | 25~300 | 4.6~16.6 USD | Start From 20 Pieces | 100 Pieces |

| TN Seires Twin Rod Pneumatic Cylinder | 10~32 | 10~200 | 7.8~39.5 USD | Start From 20 Pieces | 100 Pieces |

| CDU Series Free Installation Pneumatic Cylinder | 6~32 | 5~50 | 4.2~14.1 USD | Start From 20 Pieces | 100 Pieces |

| MGPM Series Compact Tri-rod Pneumatic Cylinder | 12~100 | 10~100 | 20.3~497.5 USD | Start From 20 Pieces | 100 Pieces |

| CPT Series Booster Pneumatic Cylinder (Hydraulic ) | 63~160 | 50~200 | 177.2~1916.3 USD | Start From 20 Pieces | 100 Pieces |

| CY Series Rodless Pneumatic Cylinder | 20~40 | 200~2000 | 62.8~295.4 USD | Start From 20 Pieces | 100 Pieces |

El flujo del proceso & Estimación de la duración

Garantizamos productos de máxima calidad mediante el riguroso cumplimiento de las normas del sector. Nuestros procesos son ISO9001:2005 y nuestro compromiso está validado por SGS y ROHS que le garantizan una calidad y fiabilidad sin concesiones.

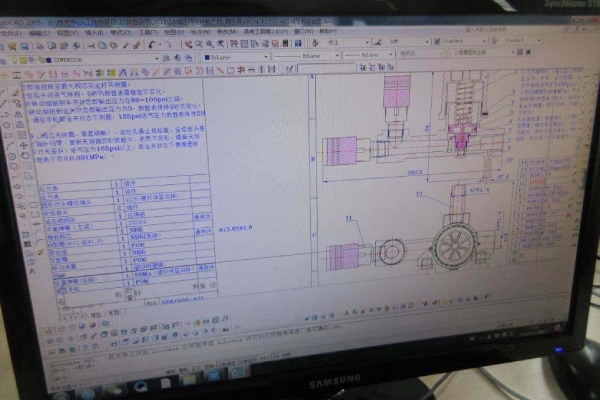

Paso 1: Comunicación del diseño del producto (3-7 días)

As leading custom pneumatic cylinder manufacturers, we engage in comprehensive communication with you to ensure a clear understanding of your product vision and requirements. We are committed to being the best pneumatic air cylinder manufacturer, focusing on clarifying specifications to establish a shared understanding of the pneumatic cylinder design. Your feedback is welcomed, and we engage in multiple discussions until you are satisfied with the design.

Paso 2: Muestreo de cilindros neumáticos (7-14 días)

Once the design meets your expectations, we, as a top pneumatic actuator manufacturer, produce samples for your review. We understand the importance of samples to you, ensuring they meet your standards in terms of quality and appearance. Your feedback is actively sought, and necessary modifications are made to ensure the final pneumatic cylinder product aligns with your expectations.

Paso 3: Pagar la factura (en el plazo de 1 día)

Una vez que confirme su satisfacción con las muestras y decida seguir adelante, el proceso de pago le resultará cómodo. Como uno de los mejores fabricantes de cilindros neumáticos, ofrecemos condiciones de pago claras como parte de nuestro compromiso con las transacciones transparentes y eficientes.

Paso 4: Fabricación a granel (30-45 días)

As a reliable pneumatic air cylinder manufacturer, upon receiving your order, we swiftly initiate bulk manufacturing. We understand the importance of timely delivery to you, while also ensuring that each pneumatic cylinder meets high-quality standards. We regularly update you on the production progress, ensuring you have a clear understanding of the entire process.

Paso 5: Envío (10-15 días)

After production is complete, we, as your trusted pneumatic cylinder manufacturers, carefully package and arrange for shipping. We provide detailed logistics information, allowing you to track the pneumatic actuators’ shipping progress. Our goal is to ensure the pneumatic cylinders reach you safely and promptly.

¿Quiere saber cómo comprimir los plazos de entrega?

With just a click, unlock a world of swift solutions! Connect with our engineers effortlessly to tailor-make a speedy pneumatic air cylinder experience.

Conocimientos básicos of Pneumatic Cylinders

Explore nuestro blog para conocer lo último en tecnología neumática. Manténgase al día sobre componentes y soluciones de vanguardia. Elíjanos para mantenerse a la vanguardia en el mundo de la innovación tecnológica.

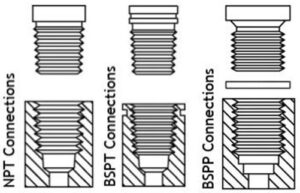

NPT vs. BSP Air Filter: A Beginner’s Guide to Choosing the Right One

NPT and BSP are two different standards for screw threads used to connect pipes and fittings. They determine how the parts fit together, how tight the seal is, and whether or not the connection will leak. Let’s take a closer look at each:

FRL Units Explained: Functions, Benefits, and Applications in Pneumatic Systems

Pneumatic systems are widely used in various industries for their ability to perform high-precision tasks using compressed air. However, to ensure these systems operate at their peak performance, the quality of the air they use is crucial. This is where the FRL unit comes into play.

Qué es la NFPA Cilindros neumáticos: Una guía completa

Los cilindros neumáticos NFPA son actuadores neumáticos diseñados de acuerdo con las normas establecidas por la National Fluid Power Association (NFPA). Estos cilindros están diseñados específicamente para ser intercambiables entre varios fabricantes.

¿Qué es un sistema neumático en un avión?

El sistema neumático de una aeronave es un conjunto de componentes diseñados para comprimir, almacenar y distribuir aire a presión a diversos sistemas de la aeronave. Este sistema proporciona un flujo constante de aire comprimido, que se utiliza para tareas como la presurización de la cabina, el aire acondicionado y el arranque del motor.

¿Qué es la norma ISO 6432 para minicilindros neumáticos?

Los sistemas de automatización y los equipos industriales requieren a menudo actuadores compactos y eficientes para realizar tareas mecánicas. El minicilindro neumático ISO 6432 ofrece un movimiento lineal de alto rendimiento en un tamaño reducido.

Guía completa para evitar errores al comprar cilindros neumáticos en China

Comprar cilindros neumáticos en China puede ser una opción rentable y fiable, pero conlleva sus propios retos. Como profesional de las compras, tendrá que sortear un laberinto de posibles escollos, desde seleccionar al proveedor adecuado hasta garantizar la calidad del producto y gestionar la logística. Esta guía está diseñada para ayudarle a tomar decisiones con conocimiento de causa, evitar errores comunes y garantizar un proceso de compra fluido.

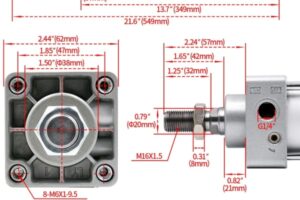

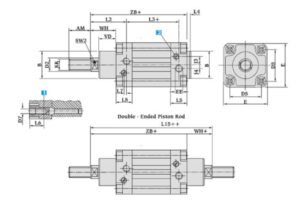

Cómo medir el tamaño de un cilindro neumático

Cuando se trabaja con sistemas neumáticos, medir con precisión el tamaño de los cilindros neumáticos es crucial para garantizar un rendimiento y una compatibilidad óptimos. Esta guía le guiará a través de los pasos y consideraciones esenciales para medir el tamaño de los cilindros neumáticos con eficacia, proporcionando una comprensión completa a los ingenieros.

Cómo calcular la fuerza de un cilindro neumático en kg

Comprender la fuerza ejercida por los cilindros neumáticos es crucial para las aplicaciones industriales. Un cálculo erróneo de esta fuerza puede provocar fallos o ineficiencias en los equipos. Esta guía proporciona un enfoque paso a paso para calcular con precisión la fuerza del cilindro neumático en kilogramos.

Cómo controlar la distancia de un cilindro neumático: Una guía completa

En el mundo de la ingeniería, el control preciso de la distancia de un cilindro neumático es crucial para optimizar el rendimiento y la eficacia. Sin un control preciso, las aplicaciones pueden sufrir ineficiencias, imprecisiones y fallos potenciales. Esta guía explora varios métodos para lograr un control preciso de la distancia del cilindro neumático, garantizando que sus sistemas neumáticos funcionen al máximo rendimiento.

¿Qué gas se utiliza habitualmente en los sistemas neumáticos?

Utilizar el gas adecuado en los sistemas neumáticos es crucial para un rendimiento y una seguridad óptimos. El nitrógeno y el aire comprimido son los gases más utilizados en diversas industrias. Conocer sus aplicaciones, ventajas y consideraciones de seguridad puede ayudar a los profesionales del sector a tomar decisiones con conocimiento de causa. Este artículo profundiza en los detalles específicos de estos gases, explorando sus propiedades únicas, aplicaciones y las razones de su uso generalizado en sistemas neumáticos.

Errores comunes Sourcing Pneumatic Cylinders from China

To ensure you procure pneumatic cylinders from China with confidence, we’ve compiled a list of common quality issues. This aims to enhance your purchasing experience, providing reliability and efficiency while ensuring the received products meet the highest standards, safeguarding your interests and confidence.

01 :Sealing Performance: Due to the industrial applications of pneumatic cylinders requiring high sealing performance, the quality of seals becomes a crucial issue. Low-quality seals may lead to air leakage, affecting the cylinder’s performance.

02:Surface Treatment: Some manufacturers may have issues with surface treatments, such as uneven coatings or susceptibility to corrosion, which can reduce the durability and corrosion resistance of pneumatic cylinders.

03:Accuracy and Dimensional Stability: Pneumatic cylinders require high precision, and dimensional instability can lead to operational problems, impacting production efficiency.

04:Material Selection: Low-quality materials can compromise the strength of the cylinder, making it prone to damage or failure. Wholesalers need to ensure that manufacturers use high-quality materials.

05:Process Control: The level of control and management in the manufacturing process directly affects product consistency and quality. Deficiencies in the manufacturing process can impact the performance and lifespan of the cylinder.

06:Performance Testing: Wholesalers should ensure that suppliers conduct rigorous performance tests on each pneumatic cylinder to ensure it complies with product specifications and customer requirements.

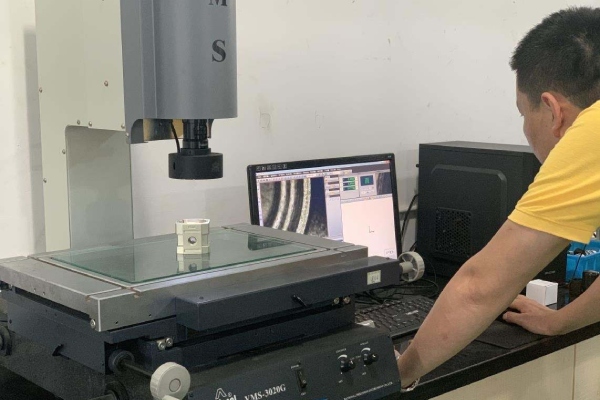

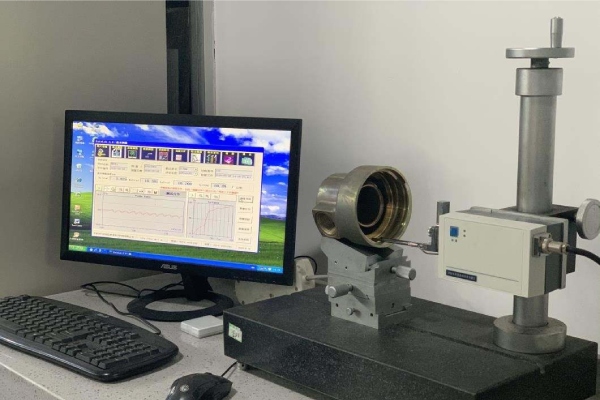

How Gymbela Control Quality

During the procurement process, you can request samples for testing, establish long-term partnerships with suppliers to have better control and assurance in terms of quality. Additionally, it is recommended to clearly outline quality standards and inspection requirements in the contract.

Resumen Autocandidatura¿Por qué elegir Gymbela?

Con 25 años de experienciagymbela es uno de los principales fabricantes de cilindros y actuadores neumáticos. Nuestras avanzadas instalaciones de 2.000 metros cuadrados, situadas en el centro de la industria neumática de China, operan dentro de una cadena de suministro rentable que incluye... Más de 300 fábricas relacionadas, gymbela ofrece servicios OEM/ODM, garantizando la calidad certificada ISO9001.

- Respaldado por el Parque Industrial PNEMÁTICO N.º 1 de China

- 100.000 unidades Cilindros neumáticos al año.

- Servicios OEM/ODM disponibles.

- Soluciones integrales de suministro de componentes neumáticos.

- Moq inferior a 100 piezas.

Elija gymbela para soluciones neumáticas de primer nivel, combinando la excelencia en la fabricación y un amplio conocimiento de la industria. Tanto si busca pedidos al por mayor como soluciones personalizadas, gymbela se adapta a sus necesidades. Póngase en contacto con gymbela ahora para asegurarse un socio fiable para la excelencia neumática, beneficiándose de nuestra cadena de suministro estable y servicios de primera calidad.

Productos neumáticos relacionados

Válvulas neumáticas

Consiga un control preciso y automatización con las electroválvulas de GYMBELA. Nuestras electroválvulas están diseñadas para una conmutación rápida, precisa y fiable del aire comprimido, lo que las hace ideales para una amplia gama de aplicaciones industriales. Sus principales características son:

- Tiempos de respuesta rápidos para un control preciso

- Alta vida útil para una mayor longevidad

- Amplia gama de opciones de tensión y conexión

- Construcción robusta para una mayor durabilidad

Air Fliters & Regulator

Proteja sus sistemas neumáticos de la contaminación y prolongue la vida útil de sus componentes con los filtros de alta calidad de GYMBELA. Nuestros filtros eliminan partículas sólidas, aerosoles líquidos e incluso vapor de aceite del aire comprimido, garantizando un rendimiento y una eficacia óptimos. Entre sus principales ventajas se incluyen:

- Alta eficacia de filtración para una máxima protección

- Elementos filtrantes fáciles de sustituir

- Construcción duradera para una larga vida útil

- Amplia gama de tamaños y grados de filtración disponibles

Airhose & Fittings

Ensure the seamless flow of compressed air throughout your system with GYMBELA’s premium Air Hoses. Designed for flexibility, durability, and efficiency, our air hoses offer the perfect solution for a wide range of industrial applications. Key benefits include:

- Materiales de alta calidad para una mayor longevidad

- Amplia gama de tamaños, longitudes y materiales de manguera para adaptarse a distintas necesidades

- Excelente resistencia a la abrasión, a la intemperie y a los productos químicos

- Fácil instalación y mantenimiento

En Preguntas frecuentes

Para mejorar la eficacia de sus compras, hemos elaborado una serie de preguntas frecuentes para abordar los problemas más comunes y ayudarle a completar rápidamente sus tareas de compra.

Is this cylinder suitable for my application ?

Gymbela recommend providing specific requirements for your application, including the needed force, speed, and other specific criteria, so our engineer can recommend the appropriate type of cylinder.

Does the size of this cylinder fit within my space constraints ?

Sure, Gymbela provide detailed dimensions and size information to ensure the cylinder can fit within your specified space.

Is the material of this cylinder corrosion-resistant ?

Yes, Gymbela manufacture cylinders using corrosion-resistant materials such as aluminum alloy 6063-T5 to ensure their reliability and durability in different environmental conditions.

What certifications do your suppliers have ?

Our factories adhere to relevant industry standards and regulations and possess the necessary certifications.such as ISO9001:2005,SGS,and ROHS. This helps ensure that the products we provide meet high-quality and safety standards.

Are additional discounts available for large-scale purchases ?

Yes, we are open to considering discounts for large-scale purchases, and we can tailor pricing plans for B2B customers to meet your budget requirements.

How do I choose a pneumatic cylinder?

When choosing a pneumatic cylinder, consider the following factors to ensure it meets your specific requirements:

01 Load Requirements: Determine the load the cylinder needs to bear, considering both vertical and horizontal loads, as well as any potential shocks or vibrations.

02 Stroke Length: Determine the stroke length of the cylinder, which is the distance the piston travels from one extreme position to another.

03 Speed: Consider the speed at which you need the piston to move. This involves cycle times in the working environment and production efficiency.

04 Operating Environment: Consider the environmental conditions the cylinder will be exposed to, including temperature, humidity, and any potentially corrosive gases or chemicals.

05 Installation Space: Determine the available installation space to ensure the selected cylinder fits within that space.

06 Cylinder Type: There are different types of cylinders, including single-acting and double-acting cylinders. Single-acting cylinders exert force in only one direction, while double-acting cylinders can generate force in two directions.

07 Materials and Seals: Choose appropriate materials to ensure the cylinder has sufficient durability in the specific environment. Additionally, the quality of seals is crucial, as they affect the performance and lifespan of the cylinder.

08 Control Method: Consider how you want to control the cylinder. Cylinders can be controlled manually, electrically, or pneumatically.

09 Cost: Finally, consider the cost of the cylinder. Ensure your choice falls within your budget and can provide the required performance.

When selecting a pneumatic cylinder, it's advisable to consult with the manufacturer or a professional pneumatic system engineer for more specific advice and customized solutions to ensure that the chosen cylinder meets your specific needs.

¿Pueden ofrecer soluciones personalizadas para nuestro sistema de automatización?

Sí, podemos ofrecerle soluciones de cilindros personalizadas que se integren a la perfección con su sistema de automatización, mejorando la eficacia de la producción. tortor. Maecenas vestibulum mollis diam.

What is the lifespan of the cylinder ?

Our cylinders are designed for long-term use, and detailed information regarding lifespan and performance is available. We can also provide a reliability guarantee to safeguard your investment.

Do you provide training or technical support ?

We offer training and technical support to ensure that your team uses and maintains the cylinders correctly, maximizing system efficiency.

Can you offer a warranty or service agreement for the cylinders ?

Yes, we provide 1 year warranties and service agreements for our cylinders. The coverage includes defects in materials and workmanship, offering you peace of mind and protection for your investment。