Pneumatic Cylinder & Actuators

China Pneumatic Cylinder Manufacturer

Gymbela, your trusted pneumatic cylinder manufacturer and wholesale supplier. With 25 years of experience in pneumatic cylinder development and production, we are an ideal choice for your business.

我々は以下を提供する flexible MOQ and wide range of customization options, so whether you run a large-scale or small-batch business, you can always find out the right solution.

Our cylinders boast a lifespan of up to 300,000 cycles, reducing your maintenance costs and enhancing production efficiency.

All our products undergo 100% professional testing, providing a continuous assurance of stable quality.

Choose Gymbela for your exceptional pneumatic cylinders, Custom solutions, professional advice, and reliable after-sales support.

How does Pneumatic Air Cylinder Work ?

A pneumatic air cylinder uses compressed air to generate linear motion in a cylindrical chamber. The compressed air creates a force imbalance, moving a piston connected to a rod. This linear motion is harnessed to perform tasks such as moving machinery components or actuating valves. Pneumatic cylinders are appreciated for their simplicity, reliability, and cost-effectiveness. They are commonly employed in manufacturing, automotive, aerospace, and robotics, particularly in applications where precise force and speed control are not crucial.

目次

It is not easy to introduce all aspects of custom Pneumatic Cylinder, so we have prepared a lot of information on this page for you to dive into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

一般 アプリケーション For Pneumatic Cylinders

Our Pneumatic Cylinders are known for excellent performance and reliability, perfect for various fields like industrial automation, manufacturing, and production lines. Boost creativity, improve efficiency, and give your business a vibrant upgrade!

製造設備

梱包設備

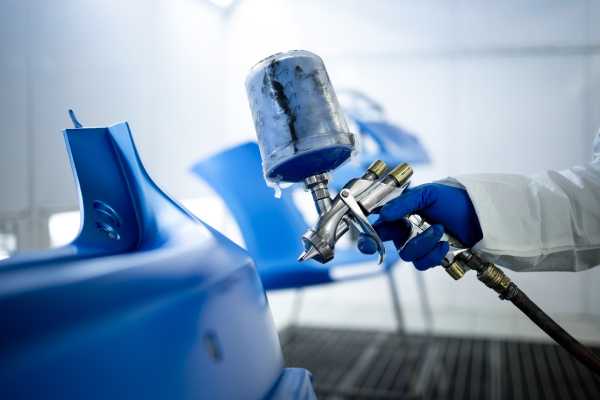

塗料スプレー装置

充填設備

マテハン機械

ロボット・エンド・オブ・アーム・ツーリング

エアーツール

種類 Pneumatic Cylinder & Actuator

Pneumatic air cylinders are devices that use compressed air to generate linear or rotary motion. They are widely used in various industrial applications for tasks such as pushing, pulling, lifting, and rotating. There are three main types of pneumatic air cylinders: single-acting cylinders, double-acting cylinders, and rotary cylinders.

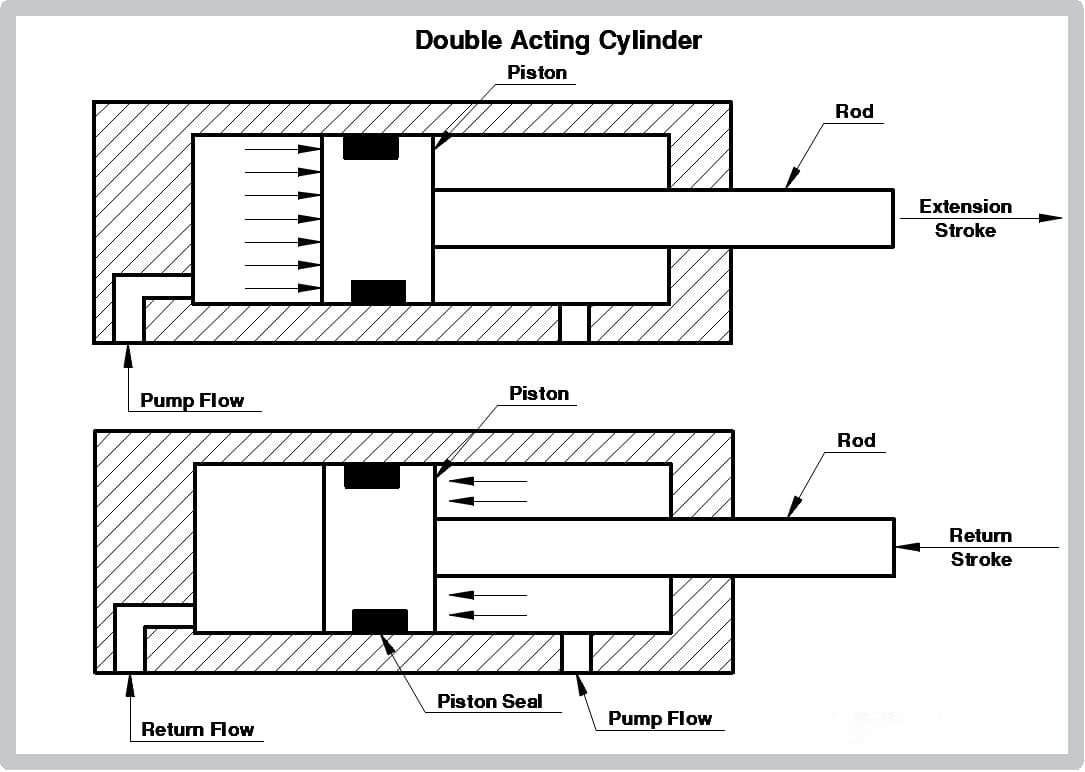

複動空圧シリンダー

- Provide bi-directional force and precise control

- applications like material handling, conveyor systems, and machine tools.

- More versatile than single-acting cylinders due to the ability to control both extension and retraction.

Double-acting cylinders use compressed air to generate force in both directions. They have a piston with two air chambers on either side, allowing for controlled movement in both the extend and retract strokes.

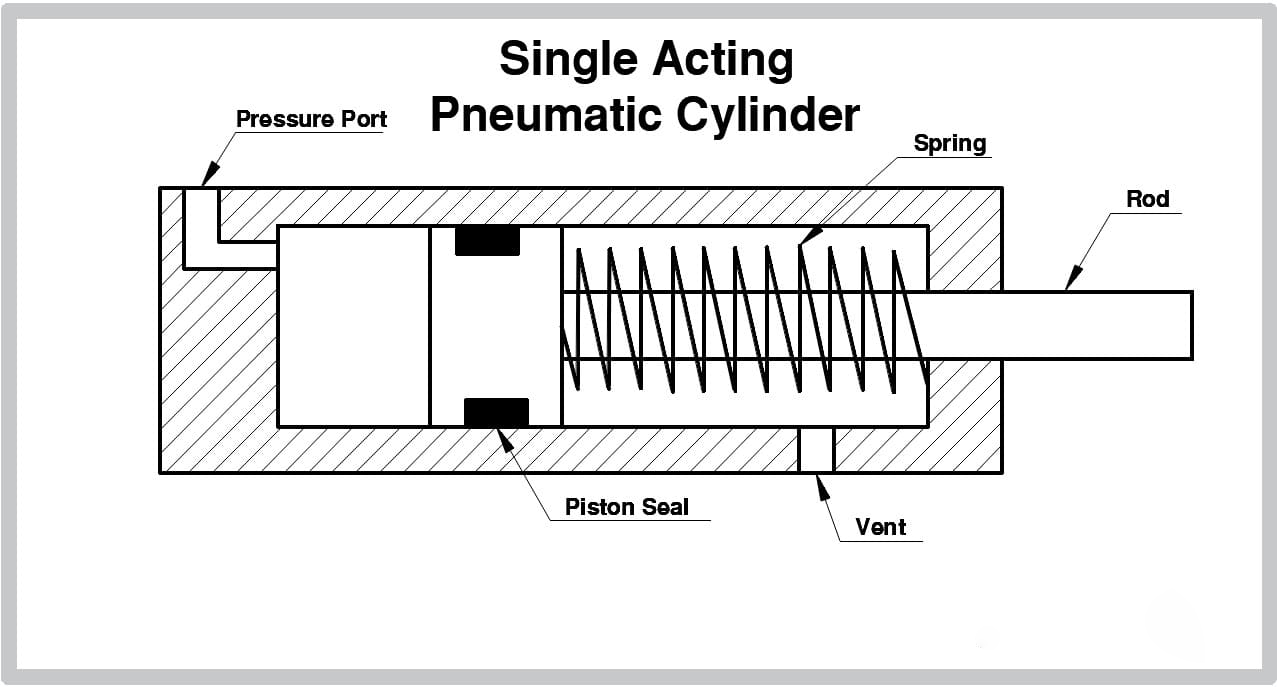

単動空気圧シリンダー

- Simple design and cost-effective.

- Suitable for applications where force is required in one direction

- Applications such as clamping, lifting, and pressing.

Single-acting cylinders use compressed air to create force in only one direction. They typically consist of a cylindrical tube, a piston, and a spring. Compressed air is used to push the piston in one direction, and the spring returns it to its original position when the air pressure is released.

ロータリー空気圧シリンダー

- Ideal for tasks such as turning valves, rotating tools, and indexing

- Available in various designs, including vane-type and rack-and-pinion.

- Suited for applications where linear motion is impractical.

Rotary cylinders convert pneumatic pressure into rotary motion. They are used when rotational movement is required instead of linear motion. The cylinder’s piston is connected to a shaft, causing it to rotate when the piston moves.

Custom Pneumatic Air Cylinders

Wanna dig deeper in Pneumatic cylinders ?

and our engineer will contact with you within 24 hours.

推定 価格 空気圧シリンダー

最終的な費用は、お客様が必要とするカスタマイズサービス、使用する原材料の仕様、関連する国の法律、および輸送距離によって異なることにご注意ください。

| 名称 | Bore(MM) | Stroke(MM) | 価格 | 在庫MOQ | カスタムMOQ |

|---|---|---|---|---|---|

| XSN Series ISO6432 Standard Pneumatic Cylinders | 8~40 | 25~300 | 4.6~20.1 USD | Start From 20 Pieces | 100 Pieces |

| XNG Series ISO15552 Standard Pneumatic Cylinders | 32~320 | 50~1000 | 8.9~1037.7 USD | Start From 20 Pieces | 100 Pieces |

| SID Series ISO15552 Double Acting Pneumatic Cylinders | 32~200 | 50~1000 | 13~496.8 USD | Start From 20 Pieces | 100 Pieces |

| ACQ Series Thin Compact Pneumatic Cylinders | 12~125 | 5~50 | 2.9~139.4 USD | Start From 20 Pieces | 100 Pieces |

| MA Series Stainless Steel Mini Pneumatic Cylinder | 16~40 | 25~300 | 5.7~20.1 USD | Start From 20 Pieces | 100 Pieces |

| MAL Series Aluminum Alloy Mini Pneumatic Cylinder | 16~40 | 25~300 | 4.6~16.6 USD | Start From 20 Pieces | 100 Pieces |

| TN Seires Twin Rod Pneumatic Cylinder | 10~32 | 10~200 | 7.8~39.5 USD | Start From 20 Pieces | 100 Pieces |

| CDU Series Free Installation Pneumatic Cylinder | 6~32 | 5~50 | 4.2~14.1 USD | Start From 20 Pieces | 100 Pieces |

| MGPM Series Compact Tri-rod Pneumatic Cylinder | 12~100 | 10~100 | 20.3~497.5 USD | Start From 20 Pieces | 100 Pieces |

| CPT Series Booster Pneumatic Cylinder (Hydraulic ) | 63~160 | 50~200 | 177.2~1916.3 USD | Start From 20 Pieces | 100 Pieces |

| CY Series Rodless Pneumatic Cylinder | 20~40 | 200~2000 | 62.8~295.4 USD | Start From 20 Pieces | 100 Pieces |

プロセスの流れ 期間推定

業界標準を厳格に遵守することで、最高品質の製品を保証します。私たちのプロセスは ISO9001:2005 また、私たちのコミットメントは次のようなものによって証明されている。 SGS そして ROHS の認証を取得し、妥協のない品質と信頼性を保証しています。

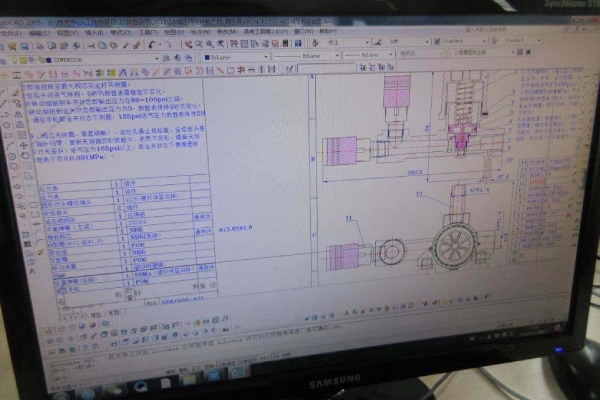

ステップ1:製品デザイン・コミュニケーション(3~7日間)

As leading custom pneumatic cylinder manufacturers, we engage in comprehensive communication with you to ensure a clear understanding of your product vision and requirements. We are committed to being the best pneumatic air cylinder manufacturer, focusing on clarifying specifications to establish a shared understanding of the pneumatic cylinder design. Your feedback is welcomed, and we engage in multiple discussions until you are satisfied with the design.

ステップ2:空気圧シリンダーのサンプリング(7~14日)

Once the design meets your expectations, we, as a top pneumatic actuator manufacturer, produce samples for your review. We understand the importance of samples to you, ensuring they meet your standards in terms of quality and appearance. Your feedback is actively sought, and necessary modifications are made to ensure the final pneumatic cylinder product aligns with your expectations.

ステップ3:請求書を支払う(1日以内)

サンプルにご満足いただき、続行することを決定された後、お支払い手続きはお客様にとって便利なものとなります。最高の空気圧シリンダーメーカーの一つとして、透明で効率的な取引へのコミットメントの一環として、明確な支払条件を提供しています。

ステップ4:バルク製造(30~45日)

As a reliable pneumatic air cylinder manufacturer, upon receiving your order, we swiftly initiate bulk manufacturing. We understand the importance of timely delivery to you, while also ensuring that each pneumatic cylinder meets high-quality standards. We regularly update you on the production progress, ensuring you have a clear understanding of the entire process.

ステップ5:発送(10~15日)

After production is complete, we, as your trusted pneumatic cylinder manufacturers, carefully package and arrange for shipping. We provide detailed logistics information, allowing you to track the pneumatic actuators’ shipping progress. Our goal is to ensure the pneumatic cylinders reach you safely and promptly.

リードタイムを短縮する方法を知りたいですか?

With just a click, unlock a world of swift solutions! Connect with our engineers effortlessly to tailor-make a speedy pneumatic air cylinder experience.

基礎知識 of Pneumatic Cylinders

最新の空気圧技術に関する洞察をブログでご覧ください。最先端のコンポーネントとソリューションの最新情報をお届けします。技術革新の世界で一歩先を行くには当社をお選びください。

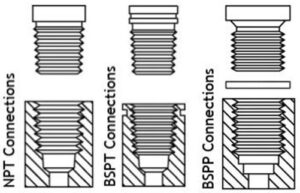

NPT vs. BSP Air Filter: A Beginner’s Guide to Choosing the Right One

NPT and BSP are two different standards for screw threads used to connect pipes and fittings. They determine how the parts fit together, how tight the seal is, and whether or not the connection will leak. Let’s take a closer look at each:

FRL Units Explained: Functions, Benefits, and Applications in Pneumatic Systems

Pneumatic systems are widely used in various industries for their ability to perform high-precision tasks using compressed air. However, to ensure these systems operate at their peak performance, the quality of the air they use is crucial. This is where the FRL unit comes into play.

NFPA空圧シリンダーとは?総合ガイド

NFPA 空圧シリンダは、全米フルードパワー協会(NFPA)が定めた規格に従って設計された空圧アクチュエータです。これらのシリンダは、さまざまなメーカー間で互換性があるように特別に設計されています。

航空機の空気圧システムとは?

航空機の空気圧システムは、加圧された空気を圧縮し、貯蔵し、さまざまな航空機システムに分配するように設計されたコンポーネントの集合体です。このシステムは、客室の加圧、空調、エンジン始動などの作業に使用される圧縮空気を安定した流量で供給します。

ISO 6432 標準ミニ空気圧シリンダーとは何ですか?

オートメーションシステムや産業機器では、機械的なタスクを実行するために、コンパクトで効率的なアクチュエータが必要とされることがよくあります。ISO 6432 規格のミニ空圧エアシリンダは、小さなパッケージで高性能なリニアモーションを実現します。

中国から空気圧シリンダーを購入する際の落とし穴を避けるための包括的ガイド

中国から空気圧シリンダーを購入することは、費用対効果が高く、信頼できる選択肢になり得ますが、それなりの課題も伴います。調達のプロとして、適切なサプライヤーの選択から、製品の品質の確保、物流の管理まで、潜在的な落とし穴の迷路をナビゲートする必要があります。このガイドは、十分な情報を得た上で意思決定を行い、ありがちなミスを避け、スムーズな購買プロセスを実現するためのものです。

空気圧シリンダーのサイズの測り方

空気圧システムの作業において、空気圧シリンダーのサイズを正確に測定することは、最適な性能と互換性を確保するために非常に重要です。このガイドでは、空気圧シリンダーのサイズを効果的に測定するために不可欠な手順と考慮事項を説明し、エンジニアに徹底的な理解を提供します。

空気圧シリンダー力(kg)の計算方法

空気圧シリンダーが発揮する力を理解することは、産業用途において非常に重要です。この力の計算を誤ると、機器の故障や非効率につながる可能性があります。このガイドでは、空気圧シリンダの力をキログラム単位で正確に計算するためのステップバイステップのアプローチを提供します。

空気圧シリンダーの距離を制御する方法:総合ガイド

エンジニアリングの世界では、空気圧シリンダの距離を正確に制御することが、性能と効率を最適化するために極めて重要です。正確な制御ができなければ、アプリケーションは非効率、不正確さ、潜在的な故障に悩まされることになります。このガイドでは、空気圧シリンダの距離を正確に制御し、空気圧システムが最高のパフォーマンスで動作するためのさまざまな方法を紹介します。

空気圧システムでよく使われるガスは?

最適なパフォーマンスと安全性のためには、空気圧システムに適切なガスを使用することが重要です。窒素と圧縮空気は、様々な産業で最も頻繁に使用されるガスです。その用途、利点、安全性を理解することは、業界関係者が十分な情報を得た上で決断するのに役立ちます。この記事では、これらのガスについて詳しく説明し、そのユニークな特性、用途、空気圧システムで広く使用されている理由を探ります。

よくある落とし穴 Sourcing Pneumatic Cylinders from China

To ensure you procure pneumatic cylinders from China with confidence, we’ve compiled a list of common quality issues. This aims to enhance your purchasing experience, providing reliability and efficiency while ensuring the received products meet the highest standards, safeguarding your interests and confidence.

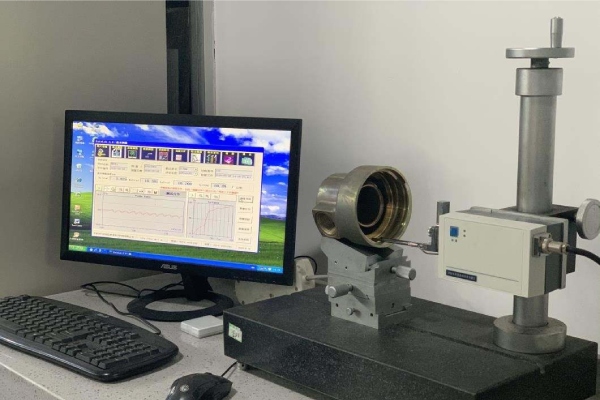

01 :Sealing Performance: Due to the industrial applications of pneumatic cylinders requiring high sealing performance, the quality of seals becomes a crucial issue. Low-quality seals may lead to air leakage, affecting the cylinder’s performance.

02:Surface Treatment: Some manufacturers may have issues with surface treatments, such as uneven coatings or susceptibility to corrosion, which can reduce the durability and corrosion resistance of pneumatic cylinders.

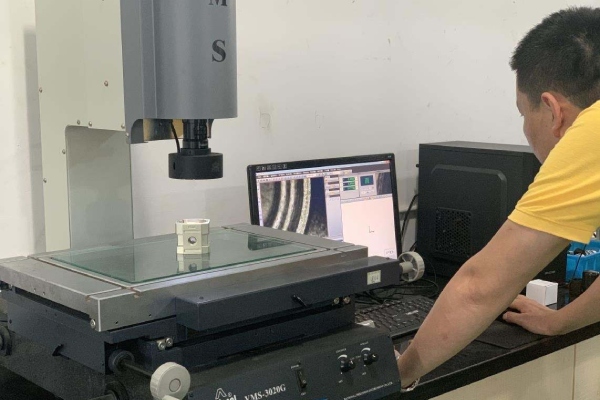

03:Accuracy and Dimensional Stability: Pneumatic cylinders require high precision, and dimensional instability can lead to operational problems, impacting production efficiency.

04:Material Selection: Low-quality materials can compromise the strength of the cylinder, making it prone to damage or failure. Wholesalers need to ensure that manufacturers use high-quality materials.

05:Process Control: The level of control and management in the manufacturing process directly affects product consistency and quality. Deficiencies in the manufacturing process can impact the performance and lifespan of the cylinder.

06:Performance Testing: Wholesalers should ensure that suppliers conduct rigorous performance tests on each pneumatic cylinder to ensure it complies with product specifications and customer requirements.

How Gymbela Control Quality

During the procurement process, you can request samples for testing, establish long-term partnerships with suppliers to have better control and assurance in terms of quality. Additionally, it is recommended to clearly outline quality standards and inspection requirements in the contract.

簡単な説明 自己推薦Gymbelaを選ぶ理由

と 25年の専門知識ジンベラは、空気圧シリンダーとアクチュエータのリーディングカンパニーです。中国の空気圧産業のハブに位置する2000平方メートルの先進的な施設では、以下のような費用対効果の高いサプライチェーンで事業を展開しています。 300以上の関連工場 gymbelaはOEM/ODMサービスを提供し、ISO9001認証の品質を保証します。

- 中国No.1のネマティック工業団地をバックに

- 100,000ユニット 空気圧シリンダー 年間。

- OEM/ODMサービスあり。

- 空気圧機器のワンストップ・ソーシング・ソリューション。

- Moqを100ピースに下げる。

卓越した製造技術と豊富な業界知識を兼ね備えた、トップレベルの空圧ソリューションをお探しなら、ぜひジンベラをお選びください。大量注文でもカスタムソリューションでも、ジンベラはお客様のニーズにお応えします。ジンベラの安定したサプライチェーンとプレミアムなサービスで、信頼できる空気圧のパートナーをお探しください。

関連空気圧製品

空気式バルブ

Achieve precise control and automation with GYMBELA’s Solenoid Valves. Our solenoid valves are designed for fast, accurate, and reliable switching of compressed air, making them ideal for a wide range of industrial applications. Key features include:

- Rapid response times for precise control

- High cycle life for increased longevity

- Wide range of voltage and connection options

- Robust construction for enhanced durability

Air Fliters & Regulator

Protect your pneumatic systems from contamination and extend the life of your components with GYMBELA’s high-quality Filters. Our filters remove solid particles, liquid aerosols, and even oil vapor from compressed air, ensuring optimal performance and efficiency. Key advantages include:

- High filtration efficiency for maximum protection

- Easy-to-replace filter elements

- Durable construction for long service life

- Wide range of sizes and filtration grades available

Airhose & Fittings

Ensure the seamless flow of compressed air throughout your system with GYMBELA’s premium Air Hoses. Designed for flexibility, durability, and efficiency, our air hoses offer the perfect solution for a wide range of industrial applications. Key benefits include:

- High-quality materials for enhanced longevity

- Wide range of hose sizes, lengths, and materials to suit various requirements

- Excellent resistance to abrasion, weather, and chemicals

- 簡単な設置とメンテナンス

について よくあるご質問

お客様の調達効率を高めるため、よくある問題を解決し、購買業務を迅速に完了できるよう、FAQシリーズを作成しました。

Is this cylinder suitable for my application ?

Gymbela recommend providing specific requirements for your application, including the needed force, speed, and other specific criteria, so our engineer can recommend the appropriate type of cylinder.

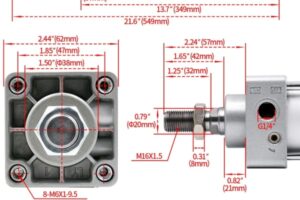

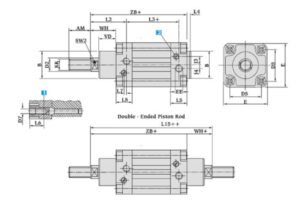

Does the size of this cylinder fit within my space constraints ?

Sure, Gymbela provide detailed dimensions and size information to ensure the cylinder can fit within your specified space.

Is the material of this cylinder corrosion-resistant ?

Yes, Gymbela manufacture cylinders using corrosion-resistant materials such as aluminum alloy 6063-T5 to ensure their reliability and durability in different environmental conditions.

What certifications do your suppliers have ?

Our factories adhere to relevant industry standards and regulations and possess the necessary certifications.such as ISO9001:2005,SGS,and ROHS. This helps ensure that the products we provide meet high-quality and safety standards.

Are additional discounts available for large-scale purchases ?

Yes, we are open to considering discounts for large-scale purchases, and we can tailor pricing plans for B2B customers to meet your budget requirements.

How do I choose a pneumatic cylinder?

When choosing a pneumatic cylinder, consider the following factors to ensure it meets your specific requirements:

01 Load Requirements: Determine the load the cylinder needs to bear, considering both vertical and horizontal loads, as well as any potential shocks or vibrations.

02 Stroke Length: Determine the stroke length of the cylinder, which is the distance the piston travels from one extreme position to another.

03 Speed: Consider the speed at which you need the piston to move. This involves cycle times in the working environment and production efficiency.

04 Operating Environment: Consider the environmental conditions the cylinder will be exposed to, including temperature, humidity, and any potentially corrosive gases or chemicals.

05 Installation Space: Determine the available installation space to ensure the selected cylinder fits within that space.

06 Cylinder Type: There are different types of cylinders, including single-acting and double-acting cylinders. Single-acting cylinders exert force in only one direction, while double-acting cylinders can generate force in two directions.

07 Materials and Seals: Choose appropriate materials to ensure the cylinder has sufficient durability in the specific environment. Additionally, the quality of seals is crucial, as they affect the performance and lifespan of the cylinder.

08 Control Method: Consider how you want to control the cylinder. Cylinders can be controlled manually, electrically, or pneumatically.

09 Cost: Finally, consider the cost of the cylinder. Ensure your choice falls within your budget and can provide the required performance.

When selecting a pneumatic cylinder, it's advisable to consult with the manufacturer or a professional pneumatic system engineer for more specific advice and customized solutions to ensure that the chosen cylinder meets your specific needs.

Can you offer customized solutions to our automation system?

Yes, we can provide customized cylinder solutions to seamlessly integrate with your automation system, enhancing production efficiency. tortor. Maecenas vestibulum mollis diam.

What is the lifespan of the cylinder ?

Our cylinders are designed for long-term use, and detailed information regarding lifespan and performance is available. We can also provide a reliability guarantee to safeguard your investment.

Do you provide training or technical support ?

We offer training and technical support to ensure that your team uses and maintains the cylinders correctly, maximizing system efficiency.

Can you offer a warranty or service agreement for the cylinders ?

Yes, we provide 1 year warranties and service agreements for our cylinders. The coverage includes defects in materials and workmanship, offering you peace of mind and protection for your investment。