Pneumatische magneetventielen

Pneumatic Solenoid Valves Manufacturer

With over 20 years of expertise, Gymbela stands out in providing OEM/ODM pneumatic solenoid valve solutions tailored to your unique requirements.

Take advantage of our solenoid valves, renowned for their impressive lifespan of 5 million cycles, effectively reducing your long-term operational expenses. Gymbela caters to your needs with precision, whether it’s for large-scale custom orders or smaller wholesale batches, ensuring a personalized touch of excellence.

Opt for Gymbela for unparalleled quality and customized solutions that take your projects to the next level. Experience the distinct Gymbela edge, where accuracy, long-lasting performance, and adaptability meet to propel your success.

Pneumatic Solenoid valves are devices that control the flow of air in pneumatic systems. Pneumatic systems use compressed air to transmit and control energy.

These valves play a crucial role in regulating the direction, rate, and pressure of the airflow in such systems.

They are commonly used in various industries and applications where automation and control are required.

How does Pneumatic Solenoid Valve Work?

Table Of Contents

It is not easy to introduce all aspects of custom Pneumatic Solenoid Valves, so we have prepared a lot of information on this page for you to dive into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

General Applications For Pneumatic Solenoid Valve

Our Pneumatic Solenoid Valve are known for excellent performance and reliability, perfect for various fields like industrial automation, manufacturing, and production lines. Boost creativity, improve efficiency, and give your business a vibrant upgrade!

Fabrication equipment

Packing Equipment

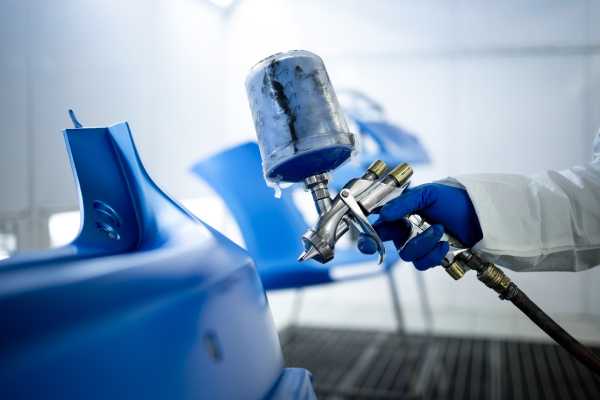

Paint spraying equipment

Filling equipment

Material Handling Machines

Robotic end of arm tooling

Air-Powered Tools

Wholesale Pneumatic Solenoid Valve

Wanna dig deeper in Pneumatic Solenoid Valve ?

Estimated Price Pneumatic Solenoid Valve

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation.

| Naam | Position & Way No. | Coil and Place | Price | Stock MOQ | Custom MOQ |

|---|---|---|---|---|---|

| 3V110 | 2-position 3-way | 1-head 2-position | 3.8~4.7 USD | Start From 100 Pieces | 500 Pieces |

| 3V210 | 2-position 3-way | 1-head 2-position | 3.8~4.5 USD | Start From 100 Pieces | 500 Pieces |

| 3V310 | 2-position 3-way | 1-head 2-position | 5~5.9 USD | Start From 100 Pieces | 500 Pieces |

| 4V110 | 2-position 5-way | 1-head 2-position | 3.8~4.7 USD | Start From 100 Pieces | 500 Pieces |

| 4V120 | 2-position 5-way | 2-head 2-position | 5.9~7 USD | Start From 100 Pieces | 500 Pieces |

| 4V130 | 3-position 5-way | 2-head 3-position | 7.9~9 USD | Start From 100 Pieces | 500 Pieces |

| 4V210 | 2-position 5-way | 1-head 2-position | 3.8~4.5 USD | Start From 100 Pieces | 500 Pieces |

| 4V220 | 2-position 5-way | 2-head 2-position | 5.9~6.5 USD | Start From 100 Pieces | 500 Pieces |

| 4V230 | 3-position 5-way | 2-head 3-position | 8.1~9 USD | Start From 100 Pieces | 500 Pieces |

| 4V310 | 2-position 5-way | 1-head 2-position | 5~5.9 USD | Start From 100 Pieces | 500 Pieces |

| 4V320 | 2-position 5-way | 2-head 2-position | 7.2~8.1 USD | Start From 100 Pieces | 500 Pieces |

| 4V330 | 3-position 5-way | 2-head 3-position | 9~10.1 USD | Start From 100 Pieces | 500 Pieces |

| 4V410 | 2-position 5-way | 1-head 2-position | 8.1~9.2 USD | Start From 100 Pieces | 500 Pieces |

| 4V420 | 2-position 5-way | 2-head 2-position | 10.1~11.3 USD | Start From 100 Pieces | 500 Pieces |

| 4V430 | 3-position 5-way | 2-head 3-position | 14~15.3 USD | Start From 100 Pieces | 500 Pieces |

The Process Flow & Duration Estimation

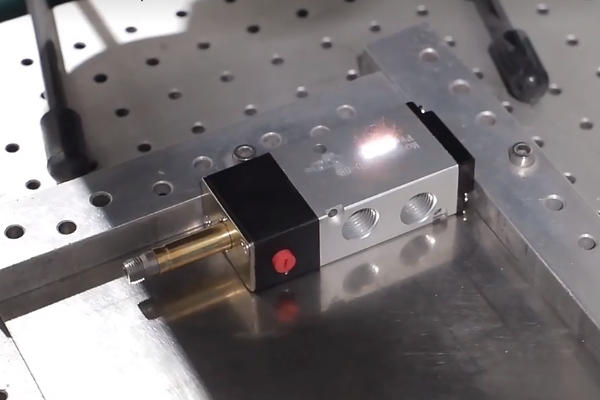

We ensure top-quality products through rigorous adherence to industry standards. Our processes are ISO9001:2005 certified, and our commitment is validated by SGS and ROHS certifications, assuring you of uncompromised quality and reliability.

Step 1: Product Design Communication (3-7 days)

As leading Pneumatic Solenoid Valves manufacturers, we engage in comprehensive communication with you to ensure a clear understanding of your product vision and requirements. We are committed to being the best Pneumatic Valves manufacturer, focusing on clarifying specifications to establish a shared understanding of the Pneumatic Valves design. Your feedback is welcomed, and we engage in multiple discussions until you are satisfied with the design.

Step 2: Pneumatic Solenoid Valves Sampling (7-14 days)

Once the design meets your expectations, we, as a top Pneumatic Valves manufacturer, produce samples for your review. We understand the importance of samples to you, ensuring they meet your standards in terms of quality and appearance. Your feedback is actively sought, and necessary modifications are made to ensure the final pneumatic cylinder product aligns with your expectations.

Step 3: Pay The Bill (within 1 day)

After you confirm satisfaction with the samples and decide to proceed, the payment process is made convenient for you. As one of the best pneumatic cylinder manufacturers, we provide clear payment terms as part of our commitment to transparent and efficient transactions.

Step 4: Bulk Manufacturing (30-45 days)

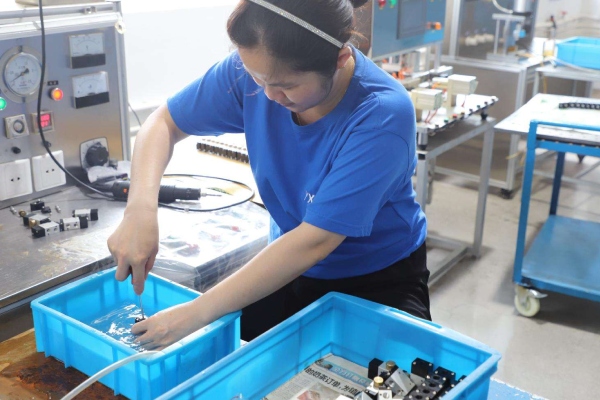

As a reliable Pneumatic solenoid Valves manufacturer, upon receiving your order, we swiftly initiate bulk manufacturing. We understand the importance of timely delivery to you, while also ensuring that each pneumatic cylinder meets high-quality standards. We regularly update you on the production progress, ensuring you have a clear understanding of the entire process.

Step 5: Shipping (10-15 days)

After production is complete, we, as your trusted Pneumatic Valves manufacturers, carefully package and arrange for shipping. We provide detailed logistics information, allowing you to track the pneumatic Valves shipping progress. Our goal is to ensure the Pneumatic Valves reach you safely and promptly.

Want to know how to compress lead times?

With just a click, unlock a world of swift solutions! Connect with our engineers effortlessly to tailor-make a speedy Pneumatic Solenoid Valves experience.

Basic Knowledge of Pneumatic Valves

Explore our blog for insights into the latest trends and fundamental knowledge in the pneumatic industry. From expert analysis to practical case studies, we provide comprehensive and concise information to keep you competitive in the field.

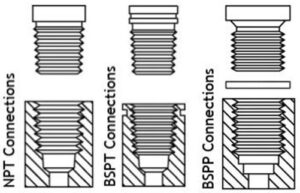

NPT vs. BSP Air Filter: A Beginner’s Guide to Choosing the Right One

NPT and BSP are two different standards for screw threads used to connect pipes and fittings. They determine how the parts fit together, how tight the seal is, and whether or not the connection will leak. Let’s take a closer look at each:

FRL Units Explained: Functions, Benefits, and Applications in Pneumatic Systems

Pneumatic systems are widely used in various industries for their ability to perform high-precision tasks using compressed air. However, to ensure these systems operate at their peak performance, the quality of the air they use is crucial. This is where the FRL unit comes into play.

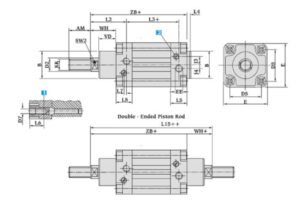

Wat is NFPA Pneumatische cilinders: Een uitgebreide gids

NFPA pneumatic cylinders are pneumatic actuators designed according to the standards set by the National Fluid Power Association (NFPA). These cylinders are specifically engineered to be interchangeable across various manufacturers

Wat is een pneumatisch systeem in een vliegtuig?

The pneumatic system in an aircraft is a collection of components designed to compress, store, and distribute pressurized air to various aircraft systems. This system provides a consistent flow of compressed air, which is utilized for tasks such as cabin pressurization, air conditioning, and engine starting.

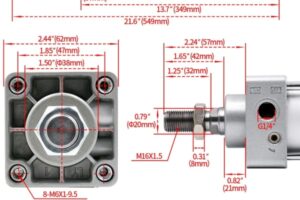

Wat is de ISO 6432 standaard mini pneumatische luchtcilinder?

Automation systems and industrial equipment often require compact and efficient actuators to perform mechanical tasks. The ISO 6432 standard mini pneumatic air cylinder delivers high-performance linear motion in a small package.

Een uitgebreide gids om valkuilen te vermijden bij de aankoop van pneumatische cilinders uit China

Purchasing pneumatic cylinders from China can be a cost-effective and reliable option, but it comes with its own set of challenges. As a procurement professional, you need to navigate through a maze of potential pitfalls, from selecting the right supplier to ensuring product quality and managing logistics. This guide is designed to help you make informed decisions, avoid common mistakes, and ensure a smooth purchasing process.

Hoe de grootte van een pneumatische cilinder meten

When working with pneumatic systems, accurately measuring the size of pneumatic cylinders is crucial for ensuring optimal performance and compatibility. This guide will walk you through the essential steps and considerations for measuring pneumatic cylinder size effectively, providing a thorough understanding to engineers.

Hoe bereken ik de kracht van een pneumatische cilinder in kg?

Understanding the force exerted by pneumatic cylinders is crucial for industrial applications. Miscalculating this force can lead to equipment failure or inefficiencies. This guide provides a step-by-step approach to accurately calculate pneumatic cylinder force in kilograms.

How to Control the Distance of a Pneumatic Cylinder: A Comprehensive Guide

In the world of engineering, the precise control of a pneumatic cylinder’s distance is crucial for optimizing performance and efficiency. Without accurate control, applications can suffer from inefficiencies, inaccuracies, and potential failures. This guide explores various methods to achieve precise control over pneumatic cylinder distance, ensuring your pneumatic systems operate at peak performance.

Which Gas is Commonly Used in Pneumatic Systems?

Using the right gas in pneumatic systems is crucial for optimal performance and safety. Nitrogen and compressed air are the most frequently used gases in various industries. Understanding their applications, benefits, and safety considerations can help industry professionals make informed decisions. This article delves into the specifics of these gases, exploring their unique properties, applications, and the reasons for their widespread use in pneumatic systems.

The Common Pitfalls When Sourcing Pneumatic Solenoid Valves

When producing pneumatic valves, there are several potential quality issues that may arise, influenced by factors such as manufacturing processes, raw material quality, equipment condition, etc. Here are some possible quality problems:

01、Sealing Issues: The sealing performance of pneumatic valves is critical, and problems like inadequate sealing or damage to sealing components may lead to gas leakage.

02、Material Issues: The use of substandard or non-compliant materials may result in components of the valve being easily damaged, corroded, or rendered ineffective.

03、Precision in Manufacturing: Insufficient precision in the manufacturing process may lead to valves being unable to open or close properly, or causing operational blockages.

04、Connection Problems: Welding, threading, or other connection methods may have issues, leading to insecure connections or easy loosening.

05、Lubrication Issues: Moving parts of the valve require appropriate lubrication, and insufficient or the use of inappropriate lubricants may result in poor movement or premature wear.

06、Insufficient Testing: If there is inadequate testing of the valve’s quality during production, potential issues may go undetected.

07、Surface Treatment Issues: Proper surface treatment of the valve is essential for preventing corrosion, improving wear resistance, etc. Inadequate surface treatment may lead to problems during valve operation.

How Gymbela Control Your Valves Quality

Conclusion: When purchasing pneumatic valves, ensure seal integrity, material compliance, reliable actuators, secure connections, air tightness, thoughtful design, machining precision, and proper surface treatment. Adhering to these considerations will help you avoid substandard products and ensure the reliability of your pneumatic valves.

A Brief Self-Nomination, Why Choose Gymbela?

With 25 years of expertise, gymbela stands as a leading pneumatic cylinder & actuator manufacturer. Our advanced 2000 sqm facility, located in China’s pneumatic industry hub, We Operating within a cost-effective supply chain involving 300+ related factories, gymbela offers OEM/ODM services, ensuring ISO9001-certified quality.

- Gesteund met China No.1 pnematic industrieel Park

- 100,000 units Pneumatic cylinders Per Year.

- OEM/ODM Services Available.

- Pneumatic Components one-stop Sourcing Solutions.

- 100% Tested Pneumatic Valves

Choose gymbela for top-tier pneumatic solutions, combining manufacturing excellence and vast industry knowledge. Whether you seek bulk orders or custom solutions, gymbela caters to your needs. Contact gymbela now to secure a reliable partner for pneumatic excellence, benefiting from our stable supply chain and premium services.

Related Pneumatic Products

Pneumatic Cylinder

Unleash the true potential of your machinery with GYMBELA’s Pneumatic Cylinders. Engineered for precision and strength, our cylinders are available in a variety of sizes, mounting styles, and materials to suit your specific needs. Key features include:

- Robust and long-lasting construction

- Low-friction seals for improved efficiency

- Enhanced temperature and pressure resistance

- Easy installation and maintenance

Pneumatic Air Fliters

Protect your pneumatic systems from contamination and extend the life of your components with GYMBELA’s high-quality Filters. Our filters remove solid particles, liquid aerosols, and even oil vapor from compressed air, ensuring optimal performance and efficiency. Key advantages include:

- High filtration efficiency for maximum protection

- Easy-to-replace filter elements

- Durable construction for long service life

- Wide range of sizes and filtration grades available

Airhose & Fittings

Ensure the seamless flow of compressed air throughout your system with GYMBELA’s premium Air Hoses. Designed for flexibility, durability, and efficiency, our air hoses offer the perfect solution for a wide range of industrial applications. Key benefits include:

- High-quality materials for enhanced longevity

- Wide range of hose sizes, lengths, and materials to suit various requirements

- Excellent resistance to abrasion, weather, and chemicals

- Easy installation and maintenance

The FAQs

To enhance your procurement efficiency, we’ve crafted a series of FAQs to address common issues and assist you in swiftly completing your purchasing tasks.

Is this cylinder suitable for my application ?

Gymbela recommend providing specific requirements for your application, including the needed force, speed, and other specific criteria, so our engineer can recommend the appropriate type of cylinder.

Does the size of this cylinder fit within my space constraints ?

Sure, Gymbela provide detailed dimensions and size information to ensure the cylinder can fit within your specified space.

Is the material of this cylinder corrosion-resistant ?

Yes, Gymbela manufacture cylinders using corrosion-resistant materials such as aluminum alloy 6063-T5 to ensure their reliability and durability in different environmental conditions.

What certifications do your suppliers have ?

Our factories adhere to relevant industry standards and regulations and possess the necessary certifications.such as ISO9001:2005,SGS,and ROHS. This helps ensure that the products we provide meet high-quality and safety standards.

Are additional discounts available for large-scale purchases ?

Yes, we are open to considering discounts for large-scale purchases, and we can tailor pricing plans for B2B customers to meet your budget requirements.

How do I choose a pneumatic cylinder?

When choosing a pneumatic cylinder, consider the following factors to ensure it meets your specific requirements:

01 Load Requirements: Determine the load the cylinder needs to bear, considering both vertical and horizontal loads, as well as any potential shocks or vibrations.

02 Stroke Length: Determine the stroke length of the cylinder, which is the distance the piston travels from one extreme position to another.

03 Speed: Consider the speed at which you need the piston to move. This involves cycle times in the working environment and production efficiency.

04 Operating Environment: Consider the environmental conditions the cylinder will be exposed to, including temperature, humidity, and any potentially corrosive gases or chemicals.

05 Installation Space: Determine the available installation space to ensure the selected cylinder fits within that space.

06 Cylinder Type: There are different types of cylinders, including single-acting and double-acting cylinders. Single-acting cylinders exert force in only one direction, while double-acting cylinders can generate force in two directions.

07 Materials and Seals: Choose appropriate materials to ensure the cylinder has sufficient durability in the specific environment. Additionally, the quality of seals is crucial, as they affect the performance and lifespan of the cylinder.

08 Control Method: Consider how you want to control the cylinder. Cylinders can be controlled manually, electrically, or pneumatically.

09 Cost: Finally, consider the cost of the cylinder. Ensure your choice falls within your budget and can provide the required performance.

When selecting a pneumatic cylinder, it's advisable to consult with the manufacturer or a professional pneumatic system engineer for more specific advice and customized solutions to ensure that the chosen cylinder meets your specific needs.

Can you offer customized solutions to our automation system?

Yes, we can provide customized cylinder solutions to seamlessly integrate with your automation system, enhancing production efficiency. tortor. Maecenas vestibulum mollis diam.

What is the lifespan of the cylinder ?

Our cylinders are designed for long-term use, and detailed information regarding lifespan and performance is available. We can also provide a reliability guarantee to safeguard your investment.

Do you provide training or technical support ?

We offer training and technical support to ensure that your team uses and maintains the cylinders correctly, maximizing system efficiency.

Can you offer a warranty or service agreement for the cylinders ?

Yes, we provide 1 year warranties and service agreements for our cylinders. The coverage includes defects in materials and workmanship, offering you peace of mind and protection for your investment。